أبواب لوحات الكهرباء عنصر مهم في أي نوع من المباني. بينما توفر حماية الوصول فقط للأفراد المصرح لهم، فإن هذه الأبواب تحافظ على مكونات الكهرباء مخفية بسلامة داخلًا. ومع ذلك، الحفاظ على هذه الأبواب بشكل صحيح هو عمل شاق ويحتاج إلى أفضل الموارد والأدوات للصيانة.

الآلات المناسبة ضرورية عند الحديث عن صيانة أبواب الألواح. تشمل الأدوات الأساسية مفك براغي، بما في ذلك أنواع العادية وفيلبس بأحجام مختلفة والتي يمكن استخدامها لتثبيت أو تخفيف البراغي داخل العديد من مفاصل الأبواب التي تحتوي على أقفال. أيضًا، جهاز اختبار الجهد هو أداة رائعة أخرى أنصح باستخدامها - ويجب استخدامها لضمان عدم وجود تيار كهربائي نشط يمر عبر اللوحة أو الدائرة أثناء عملك معها. ومع ذلك، يجب إجراء هذا الفحص بواسطة خبير قبل أن تهرع وتفتح الباب.

الألواح والتكنولوجيا والخلايا في القرن الحادي والعشرين. يمكن أن تكون التكنولوجيا الحديثة أكثر أهمية لجهة السلامة مقارنة بالوصول السهل، ويمكن أن تكون حاسمة فيما يتعلق بفتح أبواب اللوحات الكهربائية. يمكن استخدام كاميرا تصوير حراري لاكتشاف أنماط درجات الحرارة للمكونات الإلكترونية في اللوحة الكهربائية، مما يساهم بشكل كبير في تحسين عمليات الإصلاح. إذا ظهرت نقطة ساخنة، فهذا يشير إلى وجود أخطاء أو مشاكل تم تتبعها ويساعد الكهربائيين على القيام بصيانة وقائية. بنفس الطريقة، وحدة التحكم المنطقية القابلة للبرمجة (PLC) هي تقنية أخرى يمكن أن توفر تحكمًا محسنًا على أبواب الألواح، مما يوفر القدرة على ضبط عدة معلمات مختلفة لأبواب الألواح. يعتبر المروحة هواء خيارًا بارزًا، وهي مصممة لإضافة مباشرة إلى نظام التحكم أو الرصد الآلي لمبنى موجود.

إذا كان لديك قفل لكل باب، يمكن التأكد من صيانة أبواب لوحة التحكم الكهربائية. مجموعة قفل اللوحة الكهربائية الآمنة هي حزمة كاملة تأتي مع قفل، علامات وحلقات لتلبية الدور الأساسي لتأمين نظام اللوحة الكهربائية بالكامل من التلاعب. ولذلك، يجب اتباع إجراءات القفل-العلامة عند صيانة اللوحة لأن فتح الباب يتطلب إيقاف الطاقة عن اللوحة. استخدام آخر للماكينة الضاغطة للأسلاك هو أثناء صيانة باب اللوحة، حيث توفر ربطًا آمنًا وسريعًا بين الأسلاك والمحطات باستخدام مسدس تطبيق. ينبغي استخدام ماكينات ضغط الأسلاك المؤهلة فقط والتي تتوافق مع المواصفات الصحيحة.

يجب أن يتماشى اختيار المعدات المناسبة مع متطلبات كود البناء وما إلى ذلك. الحصول على متطلبات قوة المعدات وإمكانية التوافق مع لوحة الكهرباء الحالية، أولًا من شخص ذو خبرة في هذا المجال أمر حاسم. يمكن تجنب الأحمال الزائدة أو الظروف الخطرة من خلال تقييم المعدات مقارنةً بمعدل التيار الكهربائي والجهد الذي توفره اللوحة.

بالمختصر، فإن حماية أبواب اللوحات الكهربائية ستكون ضرورية للغاية. يكون امتلاك الأدوات والمعلومات الأساسية عند الحديث عن الحفاظ ليس فقط على سلامة اللوحات، ولكن أيضًا على بقائها متاحة للأفراد المصرح لهم أمرًا بالغ الأهمية. إذا تم تطبيق بروتوكولات السلامة في مكانها الصحيح، يمكن أن تساهم بشكل كبير في منع مخاطر الكهرباء. الحفاظ على النظام الكهربائي في أفضل حالاته قد يكون مهمة صعبة، لكن مع كل هذه الأدوات والمعدات المتاحة، بالإضافة إلى فهم ما يتعين عليك القيام به أثناء إجراءات الصيانة، فإنه يمكن إدارة الأمر بشكل جيد.

نقدِّم خدمات شاملة ما بعد البيع في الموقع، ومعدات خاصة بأبواب اللوحات الكهربائية تساهم في رفع درجة رضا العملاء. وعندما يتعلق الأمر بتشخيص أعطال المعدات أو احتياجات الصيانة، أو حتى احتياجات التدريب، فإننا نُجدول فوراً إرسال فرق فنية إلى الموقع لحل المشكلات في الوقت المناسب، مما يضمن استمرارية الإنتاج السلسة وأداء عملائنا بكفاءة.

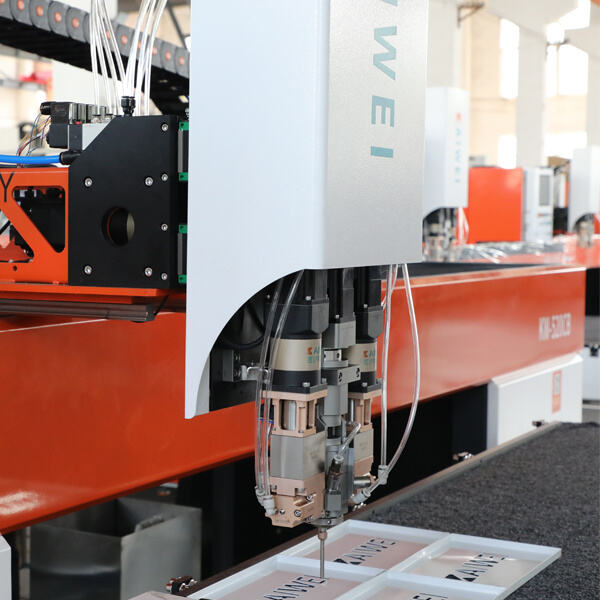

تتميَّز الرؤوس الهجينة KW-900 بمزايا براءات اختراع وطنية. ولا يتطلب الأمر أي معدات خاصة بأبواب اللوحات الكهربائية أو أنظمة للتحكم في الضغط (حيث تعيق الظروف المناخية طوال العام إجراء قياسات متكررة لكثافة المادة الأولية). ويمكنك تعديل معايير الشاشات، مثل حجم الشاشة ومقدار الغراء المُرشَّح، لتناسب احتياجاتك.

تستخدم آلاتنا تصميمًا متكاملًا، ما يجعلها أكثر ملاءمةً لأبواب لوحات التحكم الكهربائية؛ ولا تتطلب عمليات احترافية، مما يقلل من عبء العمل الملقى على عاتق العمال؛ ويعزّز الإنتاجية. كما أن تشغيلها سهلٌ جدًّا، ويمكن للمبتدئين البدء في استخدامها خلال ٣٠ دقيقة فقط، ما يبسّط خطوات الإجراء.

ماكينات كايوي الآلية بالكامل لوضع الحشوات الرغوية هي معدات مخصصة لأبواب لوحات التحكم الكهربائية، وتضم ٨ محركات. كما تأتي مزودةً بـ ٨ مخفضات و٤ مضخات قياس.

حقوق النسخ © شركة شنغهاي كايوي للتكنولوجيا الذكية (المجموعة) المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية-المدونة