تعد آلات توزيع البولي يوريثين ذات أهمية قصوى في عملية التصنيع لأنها تعمل كمزوّد كفؤ لتطبيقات الرغوة والختم. ومع توفر العديد من النماذج والأنواع المختلفة في السوق، يمكن أن يكون اختيار الجهاز المناسب لعملك أمرًا صعبًا جدًا. يتضمن هذا الدليل - الذي يتم تنظيمه من أفضل آلات توزيع البولي يوريثين للاستخدامات الصناعية إلى الوحدات الحاصلة على أعلى التقييمات والمخصصة لتطبيق الرغوة بدقة - بعض النقاط التي تساعد في اتخاذ القرار.

استخدام صناعي لآلات توزيع البولي يوريثين التي تكون الأكثر كفاءة وستعمل بشكل مثالي لإدارة الإنتاج الأعلى بينما تظل جدًا موثوقة، قوية ومُلِمة. على سبيل المثال، سلسلة H-XP من Graco هي حل حديث لتوزيع المواد مزود بنظام هيدروليكي فائق الكفاءة لتطبيق الرغوة بدقة وسرعة على الأسطح مثل الأسقف، الجدران أو الأرضيات بمعدل يصل إلى 54 رطلاً/الدقيقة. بالإضافة إلى ذلك، توفر هذه السلسلة واجهة مستخدم ودية تبسط وظائف الجهاز من خلال شاشات اللمس لزيادة الإنتاجية.

سلسلة H-XP مصممة لتطبيقات صناعية ذات إنتاجية عالية ويمكن أن تُستخدم مع عدة مسدسات رش من Graco مثل Fusion، Probler P2 أو GX-7 لتلبية احتياجات القطاعات المختلفة. كما أن هذه السلسلة متوافقة مع تقنيات البرمجيات المتقدمة، بما في ذلك Graco InSite لمراقبة عن بعد، وبيانات السوائل في الوقت الفعلي، ومساعدة في تشخيص المشكلات لتحسين الأداء وتسهيل الصيانة.

عندما يتعلق الأمر بتطبيق الرغوة بدقة، فإن الأفضل من آلات توزيع البولي يوريثين العلوية يضمن جودة عالية لتوزيع الأصول بشكل مدرب وثابت. يعتبر ExactaBlend™ AGP من نوردسون مثالاً رائعاً على ذلك، حيث يشمل ميزات مثل تصميم مزدوج المحرّك الرائد في الصناعة لتقديم اهتزاز ثابت، وصمام توزيع يتم التحكم به بواسطة محرك سيرفو لتقديم ضبط دقيق على معدل وكمية تدفق السائل. بالإضافة إلى ذلك، يستخدم ExactaBlend™ AGP نظام تسليم الصبغة ColorMax™ 2 من نوردسون -- وهو منتج متقدم يعتمد على الطيفي والذي يقدم مراقبة وتحكم في الخط أثناء التشغيل للتأثيرات الكرومية مما يضمن إنتاج منتجات رغوية ذات جودة عالية.

نظام ExactaBlend Meter يزيل كل العمليات القياسية ويركز بشكل كامل على كل مادة يقوم بقياسها بشكل متزامن بمساعدة محطات توقف تلقائية تمنع أي تداخل من جانب إلى آخر - مما يقلل الهدر ويزيد الإنتاجية. جميع هذه العناصر تتجمع لتجعل منExactaBlend™ AGP نظامًا مثاليًا للضغط التدريجي باستخدام المكابس مع دقة خاصة في تطبيق الرغوة.

العوامل التي يجب أخذها بعين الاعتبار عند اختيار ماكينة توزيع البولي يوريثان لعملك

اختيار ماكينة توزيع البولي يوريثين المناسبة يعتمد على العديد من العوامل مثل نوع وحجم التطبيقات المطلوبة، ومقدار الميزانية المتاحة، وأهداف كفاءة الإنتاج. أحد العوامل الحرجة هو ما إذا كنت بحاجة إلى طريقة يدوية أو آلية للقيام بالأشياء. تكون الأنظمة اليدوية عادة أقل تكلفة، لكنها تتطلب المزيد من العمل وقد توفر دقة قليلة. في المقابل، تكون الأنظمة المتقدمة الآلية أكثر دقة على الرغم من أنها قد تتطلب استثمارًا أوليًا.

الشيء الثاني الأكثر أهمية الذي يجب مراعاته هو الرغوة أو المادة اللاصقة المستخدمة. بعض الآلات تناسب بشكل أفضل المواد ذات اللزوجة المنخفضة، بينما تم تصميم البعض الآخر للمواد ذات اللزوجة العالية أو التطبيقات الأكثر تحديًا. النقطة الرئيسية الأخرى التي يجب أخذها في الاعتبار هي سعة الإخراج للآلة، حيث تخبرك بمقدار المادة التي يمكن رشها في الدقيقة أو الساعة. بينما يمكن للأجهزة ذات الإخراج العالي أن ترش بشكل أسرع وهي أكثر تكلفة.

احفظ أموالك مع آلات توزيع البولي يوريثين، للعزل الأفضل وتطبيق المواد اللاصقة

آلات توزيع البولي يوريثين مفيدة جدًا في توفير حلول فعالة لعزل وتطبيق المواد اللاصقة، خاصة فيما يتعلق بصناعات البناء والعزل. نظام Reactor™ E-10hp من Graco هو نظام قوي يوفر رشًا متميزًا للعزل، طبقات سطح السقف، وتطبيق البولي يوريا عند درجة حرارة الغرفة. تم تصميم E-10hp لتقليل تكاليفك وزيادة الإنتاجية بفضل إخراجه العالي والخيارات المعدة مسبقًا على هذه الآلة السهلة الاستخدام.

تم تصميم E-10hp للعمل مع مسدس الرش Fusion AP® من Graco، والذي يخلق مجموعة واسعة من الأنماط ويسمح لك باختيار مختلف مستويات اللزوجة للمواد لتحقيق عزل وكفاءة عالية في التطبيقات اللاصقة. تحتوي الآلة أيضًا على وقت توقف أقل وإعادة ملء أسهل للحاوية مما يقدم حلًا نظيفًا لعزل وتطبيق المواد اللاصقة.

![أفق الابتكار في ضغط البولي يوريثين ومزاياه التي تزيد من الكفاءة وكذلك [KWT1]](https://shopcdnpro.grainajz.com/1190/upload/product/b8af06566a44aadc09ec3ffc8a452e14e452d0fef6730a171416efe5422a1295.jpg)

سابقًا، كانت هذه العملية تُنجز باستخدام طرق بدائية ومتعبة تتطلب جهدًا بدنيًا كبيرًا وتقدم نتائج غير دقيقة، ثم تطورت لتصل إلى أنظمة آلية عالية التكنولوجيا تحتوي على مكونات أداة نهاية الذراع المتكاملة (EOAT) التي تحول هذا الحركة ثنائية الأبعاد البسيطة إلى عملية أكثر تسلسلاً لتحقيق إنتاجية وكفاءة أفضل. ما نعرفه بالفعل هو أن التكامل الحديث لتقنيات "الذكاء" لرصد عن بعد وتحليل البيانات في الوقت الفعلي أصبح ملحوظًا مؤخرًا. مثال على ذلك هو نظام Graco's InSite™، وهو نظام برمجي قابل للتوسع يتيح مراقبة ومراقبة عن بعد لعمليات توزيع البولي يوريثين، والذي يتضمن تنبيهات وتشخيصات عند استخدامه مع سلسلة H-XP أو أجهزة Fusion.

تطور حديث آخر: أنظمة الروبوتات للتوزيع الكيميائي بطريقة أكثر دقة واستمرارية وسرعة. يمكن لهذه الروبوتات اتباع المسارات لتوزيع المواد بدقة مع تقليل الأخطاء البشرية، كما أنها قادرة على العمل 24/7 دون الشعور بالتعب.

يمكن أن تكون المتطلبات تقنية توزيع البولي يوريثين تحديًا، ودفع الحاجة إلى التحكم القابل للتكرار والدقة الأكبر عند السرعات العالية إلى تحسينات مستمرة عبر مجموعة واسعة من التطبيقات. سيكون هناك المزيد من الأتمتة، التحكم الذكي، وحلول البرمجيات التي يمكن للمصنعين تنفيذها في عملياتهم الإنتاجية لزيادة إنتاجيتهم وجودة منتجاتهم.

لا شك أن آلات توزيع البولي يوريثين تعد جزءًا لا يتجزأ من صناعة التصنيع. اختيار الآلات المناسبة وفقًا لاحتياجاتك سيساعد على زيادة الإنتاجية والكفاءة وتقليل هدر المواد. قبل اتخاذ القرار، قم بتقييم التطبيقات ومتطلبات الحجم لعملياتك وكذلك القيود الميزانية لتحديد أهداف كفاءة الإنتاج. فكر في الرغوة والختم الذي سيتم تطبيقه، بالإضافة إلى قدرات الإخراج لتطبيقك. تعرف على أحدث التطورات التكنولوجية في توزيع البولي يوريثين، بما في ذلك التحكم الذكي والروبوتات التي يمكن أن تساعدك على العمل بكفاءة أكبر مع ميزة تنافسية.

لا حاجة لتشغيل احترافي؛ فهي تقلل عبء العمل الملقى على عاتق الموظفين، وسهلة الاستخدام. ويمكن للمستخدمين المبتدئين تشغيل آلة توزيع البولي يوريثان.

تقدم شركتنا خدمات ما بعد البيع الموسعة على الموقع بالإضافة إلى جهاز توزيع البولي يوريثان لتحسين تجربة العملاء وضمان الرضا. سنرسل الأفراد إلى الموقع لصيانة المعدات أو التدريب أو حل المشكلات من أجل إصلاح المشكلة بسرعة وفي الوقت المناسب. وهذا يضمن أن تكون معدات العملاء قادرة على الاستمرار في التشغيل والإنتاج بطريقة طبيعية.

حصلت رؤوس الهجين KW-900 على براءات اختراع وطنية. ولا يتطلب الأمر قياس المواد الأولية، ولا التحكم في الضغوط (إذ إن الظروف المناخية طوال العام تعيق إجراء قياسات متكررة لكثافة المواد الأولية). ويمكن تعديل آلة توزيع البولي يوريثان حسب احتياجاتك، مثل أحجام شاشة النظام ومقدار الغراء المنبعث.

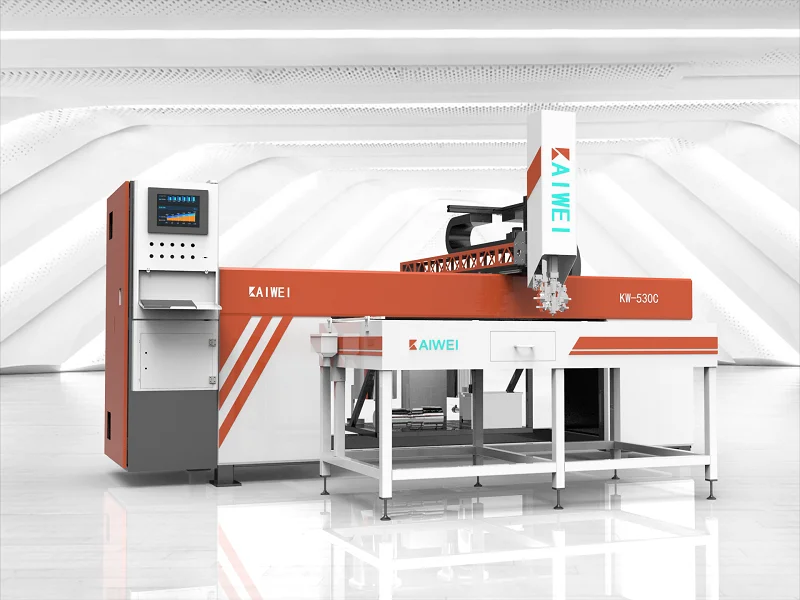

وفي اختبارات مستويات الحماية، يمكن أن تصل درجة حماية الغلاف المزود بأقراص ختم رغوية إلى IP67 أو أعلى. كما أننا نمتلك شهادات المطابقة الأوروبية (CE). وتزود آلة توزيع البولي يوريثان من شركة كايوي بـ ٣ محاور و٨ محركات تخفيض و٨ محركات سيرفو و٤ مضخات قياس.

حقوق النسخ © شركة شنغهاي كايوي للتكنولوجيا الذكية (المجموعة) المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية-المدونة