آلة الحقن أداة قوية تمكنك من إنتاج منتجات رغوية بما في ذلك الفراش، الوسائد وحتى مقاعد السيارات! إنها أفضل آلة وهي تعمل بشكل أسرع بسبب الرغوة الفريدة التي تسمى البولي يوريثين. رغوة البولي يوريثين هي أيضًا مادة تكون ناعمة وقوية في نفس الوقت، مما يجعلها مناسبة للاستخدام في تصنيع الهياكل. كونها مريحة ومتينة، يجعلها مثالية للعناصر المصممة لتستمر لفترة طويلة.

تبدأ هذه الآلة بخلطة من سائلين، الأول هو البوليول والثاني هو الإيزوسيانات. عندما يتم خلط هذين السائلين معًا، فإنهما يتفاعلان بطريقة ما. تأكد من خلطهما بشكل جيد ثم أدخل الخليط إلى قالب (الشكل الذي تريد أن يكون عليه رغوة). يبدأ الخليط في الارتفاع والتضخم حتى يملأ القالب بالكامل. العملية المستخدمة تصبح إعدادًا لمنتج الرغوة، ويتم تحضيره في شكل قوي وبالتالي يمكن العمل به بسهولة. الجزء العظيم هو أنه يمكنك صنع أي شكل أو حجم! هذا يعني أن بإمكانك إنشاء منتجات تكون تمامًا كما تم الإعلان عنها.

تُمكّنك ماكينة الحقن من أن تكون أفضل وأكثر كفاءة في التعامل مع المواد. المشكلة مع الكثير من طرق صنع الرغوة هي أنه عند تصنيع المنتجات، غالبًا ما تهدر كميات كبيرة من موادك النفيسة والمنفوخة. وهذا أمر مزعج لأنه يمكن أن يكون مضيعة شديدة للمواد والأموال دون فائدة. ومع ذلك، يمكنك إدارة كمية الرغوة التي يتم حقنها في القالب بشكل أفضل عند استخدام ماكينة الحقن. FloatTensor => [ hoos_for_l10n ]_BY ولذلك، يعني ذلك أقل إهدارًا وأكثر كفاءة لتوفير المال والمصادر!

شيء آخر رائع جدًا حول ماكينة الحقن - يمكنك حتى تصنيع المنتجات بشكل أسرع. بعض الطرق الأخرى لصنع الرغوة قد تستغرق وقتًا طويلاً وتكون بطيئة. لكن هذه الماكينة تسمح لك بتصنيع هذه المنتجات بشكل أسرع بكثير مما كنا نستطيع القيام به من قبل. وهذا يثبت فائدته بشكل كبير عندما يكون لديك طلب كبير يجب تنفيذه خلال دقائق.

تم تصنيع هذه الآلة لإنتاج الرغوة وملء العديد من القوالب في وقت واحد، لذا يمكنك إنشاء المزيد من المنتجات في وقت أقل. يمكن لهذه القدرة على العمل على عدد من القوالب تقليل وقت الاستجابة الخاص بك والحفاظ على قدرتك على تلبية جميع الطلبات من العملاء. في وقت أقل بكثير، يمكنك إنتاجها بشكل أسرع وبالتالي قبول المزيد من الطلبات لمساعدتك على نمو عملك أكثر!

شراء آلة حقن رغوة البولي يوريثين استثمار ذكي في عملك يمكن أن يساعدك في التأكد من أن كل المنتجات التي تخرج من المصنع، بغض النظر عن عددها أو الزمن بين تصنيعها، يتم إنتاجها بأعلى مستوى ممكن. ويمكنك التحكم في جودة وكمية الرغوة المستخدمة في أي منتج بهذه الآلة. فهي تتيح لك إنشاء بالضبط ما يبحثون عنه.

آلة الحقن أيضًا تكون جدًا متسقة. لكل قالب، تقوم بتوزيع كمية متساوية من خليط الرغوة بحيث يتم صب كل منتج بنفس الطريقة. هذه الاتساق ضروري إذا كنت ترغب لأن يكون علامتك التجارية ذات سمعة جيدة وهي أيضًا تساعد في إرضاء العملاء. الناس يحبون علامتك التجارية ويعودون لشرائها منك، لأنهم يعرفون بيقين ما هي جودة منتجاتك.

توفّر شركتنا آلة حقن رغوة البولي يوريثان، كما توفّر تطبيقات تعلُّم إلكترونية مبتكرة عبر الإنترنت لتحسين تجربة العميل وضمان رضاه. ويمكننا إرسال فرق فنية إلى الموقع لتقديم الدعم في مجال الصيانة أو التدريب أو تشخيص الأعطال وحلها بسرعة وكفاءة. وهذا يضمن أن يواصل عملاؤنا عملياتهم التشغيلية وإنتاجهم بشكل طبيعي.

لا يتطلب تشغيلها خبرةً احترافيةً؛ فهي تقلل عبء العمل الملقى على عاتق الموظفين، وسهلة الاستخدام. ويمكن للمستخدمين المبتدئين تشغيل آلة حقن رغوة البولي يوريثان بسهولة.

رؤوس ماكينة حقن رغوة البولي يوريثان مسجلة ببراءات اختراع رسمية في الولايات المتحدة. ولا تقوم هذه الرؤوس بقياس المواد الأولية، كما أن التحكم في الضغط مطلوب (فإن الظروف المناخية طوال العام تجعل من المستحيل قياس كثافة المادة الأولية). ويجوز تعديل معايير الشاشة وحجمها ومقدار الغراء المُرشَّح لتناسب احتياجاتكم.

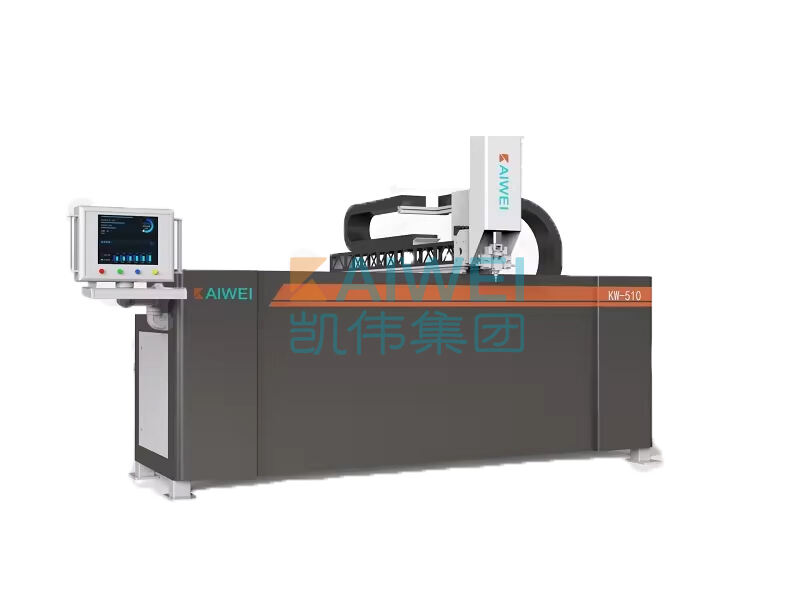

جهاز ختم الرغوات بالكامل أوتوماتيكيًا من شركة كايوي مزوَّد بثلاث محاور بالإضافة إلى ماكينة حقن رغوة البولي يوريثان. كما يحتوي على ٨ مخفضات و٤ مضخات قياس.

حقوق النسخ © شركة شنغهاي كايوي للتكنولوجيا الذكية (المجموعة) المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية-المدونة