إنها رغوة شائعة جدًا ونعرفها بشكل يومي في حياتنا، حتى لو بدا لنا أنها مادة خام عادية قد تشعر بأنها العكس تمامًا. واحدة من أكثر الأنواع انتشارًا هي رغوة البولي يوريثين. الرغوة هي مزيج من أنواع مختلفة من المواد الكيميائية المعروفة بإنتاج مادة صلبة ومتينة للغاية يمكن استخدامها في عدد من المنتجات.

لهذا السبب فإن المواد الكيميائية المذكورة أعلاه في رغوة البولي يوريثين (PU Foam) مهمة جدًا؛ فهي تساعدنا في تتبع أو وصف كيفية عملها بشكل أفضل. تتكون رغوة البولي يوريثين بشكل أساسي من مادتين كيميائيتين، هما البوليوال والديإيزوسيانات. هاتان المادتان لاعبان أساسيان، لكنهما فقط مادتان... ويجب إضافتهما مع الصوص السري. عندما تُدمج هاتان المادتان الكيميائيتان، فإنهما تطلقان استجابة كيميائية عنيفة، وهذه الاستجابة هي التي تُنشئ الرغوة التي ترتفع وتتجمد إلى كتلة صلبة قابلة للاستخدام.

في الواقع، هذا هو العكس قليلاً لنهاية بعض الأمور الأكثر أهمية في إنتاج رغوة البولي يوريثين. يتكون البوليول داخل رغوة البولي يوريثين من (الأساس) مستخلصات الزيوت ويأتي من مصادر مختلفة. يتم تسخين الزيوت والتفاعل مع سلسلة من البوليمرات لإنشاء البوليول. البوليول: هذا هو المكون الأساسي للرغوة، والذي يحافظ على شكلها وتصميمها عن طريق الحفاظ عليها ناعمة.

دي آيزوسايانت - إنه أحد المكونات الكيميائية الرئيسية المستخدمة في إعداد رغوة البولي يوريثين، حيث يحتوي على ذرتين من النيتروجين وزوج واحد من الكربون. تتمدد الرغوة وتصلب بسرعة كبيرة بمجرد خلط دي آيزوسايانت مع البوليول. السبب في ذلك هو أن كلا الجزئين (البوليول وكذلك دي آيزوسايانت) ضروريان لتشكيل رغوة البولي يوريثين.

رغوة البولي يوريثين (PU) المستخدمة للعزل (لحفظ الأشياء دافئة أو باردة). تحتوي هذه الرغوة على فقاعات هواء دقيقة، وهي السمة الأساسية لرغوة البولي يوريثين. يمكن الحفاظ على درجة حرارة المادة عند المستوى المطلوب بسبب هذا الهواء المحبوس، مما يجعلها واحدة من أفضل العوازل. وعلى الرغم من أنها تساعد في الحفاظ على الدفء في الشتاء والبرودة في الصيف، فإن ذلك يعتبر ميزة جيدة في العديد من الظروف.

طريقة الإنتاج التي يتم بها تصنيع رغوة البولي يوريثين (PU) ستحدد التطبيق النهائي. على سبيل المثال، عند استخدام مادة مثل البولي إيزوسيانات مثل 2،4- تولوين ديإيزوسيانات لصنع رغوة PU وإذا تم استخدام كمية زائدة من 2،4- TDI، فإن المادة ستكون صلبة للغاية، مما يؤدي إلى تقليل عمرها الافتراضي وقد تزول تحت وزنها الخاص. من ناحية أخرى، إذا تم استخدام كمية كبيرة من البوليول، فقد تصبح الرغوة ناعمة ومطاطية للغاية بحيث لا توفر قوة كافية لتقديم الدعم.

تجعل الخصائص الباهرة لرغوة البولي يوريثين استخدامها شائعًا حولنا في معظم الأشياء اليومية. يمكن أن تكون موجودة في أثاث المنزل، مثل الكنب والكراسي؛ ومراتب تتيح لك النوم براحة طوال الليل؛ وفي جميع أنحاء السيارة مما يسمح بنقل آمن في حالات التصادم. عندما نستخدمها في منازلنا كعزل حراري، فإنها تسخن وتبرد الهواء نفسه للتحكم في درجة الحرارة المناسبة.

تمتلك رؤوس تركيب رغوة البولي يوريثان (PU) براءات اختراع رسمية في الولايات المتحدة الأمريكية. ولا تقيس هذه الرؤوس المواد الخام، بل يتطلب الأمر التحكم في الضغط (وبما أن الظروف المناخية تتغير على مدار العام، فإن قياس كثافة المادة الخام يصبح مستحيلاً). ويمكن تعديل معايير الشاشة وحجمها ومقدار الغراء المُرشَّح لتناسب احتياجاتك.

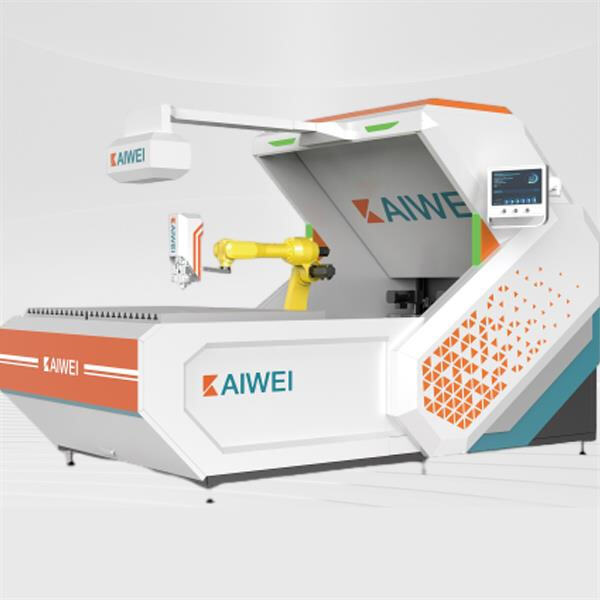

توفّر شركتنا خدمات ما بعد البيع الموسعة على الموقع لتحسين تجربة العملاء وضمان الرضا. سنرسل الأفراد إلى الموقع لصيانة المعدات أو التدريب أو حل المشكلات من أجل إصلاح المشكلة بسرعة وفي الوقت المناسب. وهذا يضمن أن تكون معدات العملاء قادرة على الاستمرار في العمل والإنتاج بشكل طبيعي.

لا حاجة إلى تركيب كيميائي لرغوة البولي يوريثان (PU)، ما يقلل عبء العمل الملقى على عاتق الموظفين. كما أن التشغيل سهل للغاية، ويستطيع المستخدمون الجدد البدء في الاستخدام خلال ٣٠ دقيقة.

مُختومات كايوي للرغوة بالكامل أوتوماتيكية مزودة بـ ٣ محاور و٨ محركات، كما تأتي مزودة بـ ٨ مخفضات بالإضافة إلى تركيب كيميائي لرغوة البولي يوريثان (PU).

حقوق النسخ © شركة شنغهاي كايوي للتكنولوجيا الذكية (المجموعة) المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية-المدونة