هل أنت عاشق للوسادات، والوسائد، والمراتب ومنتجات مختلفة من جودة الرغوة! الآن، إذا توقفت لتفكر في ما يجب أن تكون مصنوعة منه... المادة هي في الواقع رغوة الـ PU، والتي تعني رغوة البولي يوريثين. رغوة الذاكرة هي نوع من الرغوة تم استخدامه في العديد من العناصر المختلفة لأنها تجعل المنتج قويًا وموثوقًا للغاية، ومريحًا أيضًا لأنك لا تزال تستطيع تشكيله إلى أي شكل يناسب احتياجاتك. كثافة رغوة الـ PU: نقطة حاسمة يجب ملاحظتها فيما يتعلق بالرسم البياني أعلاه هو أنها تشير بشكل خاص إلى أغطية الأرضيات القابلة للنقل، والمتداخلة وتلك التي يتم تركيبها في الموقع (حسب النوع الذي يناسب مكان التمرين الخاص بك)، بدلاً من الأفضل إذا لم تقم حتى الآن بدفن بعض السجاد الثقيل تحت السجاد العادي... الكثافة، بين عوامل أخرى تحكم كيف ستشعر الرغوة وكيف ستؤدي. كثافة الرغوة: ما هي، وكيفية قياسها ولماذا تهم؟ والعوامل التي تؤثر على الرغوة؟

أهمية كثافة رغوة البولي يوريثين. هذا أمر بالغ الأهمية لأنه يمكّنك من تحديد مجموعة واسعة من الخصائص مثل مدى متانة المادة، قوتها، نعومتها أو مدة بقاء مادة البولي يوريثين. الرغوة ذات الكثافة العالية تشير إلى رغوة أثقل وأكثر متانة يمكنها دعم وزنك دون أن تُضغط. هذه الرغوة المتمددة تلقائيًا هي الخيار المثالي للأغراض التي تحتاج إلى دعم إضافي - مثل الفرش، مقاعد السيارات، وكراسي المكتب حيث يجلس الناس طوال اليوم.

من ناحية أخرى، الرغوة ذات الكثافة المنخفضة خفيفة ومرنة مما يجعلها أكثر نعومة ومناسبة للأرائك، الوسائد أو الألعاب المليئة. في بعض الأحيان، يقوم الصناعون بمزج الرغوة ذات الكثافات المختلفة معًا لإنتاج عناصر تكون داعمة ومريحة في نفس الوقت. على سبيل المثال، يمكن لنموذج واحد أن يكون به وسادة مقعد صلبة وظهر ناعم لتلك اللحظات التي تريد فيها الاسترخاء ولكن لا تزال بحاجة إلى الدعم.

يمكن أن تكون رغوة البولي يوريثين (PU foam) ذات جودة مختلفة لأسباب متعددة. قد تشمل هذه الأسباب كثافتها، والمواد الكيميائية المستخدمة في تصنيعها، وكيفية إنتاج الرغوة وما كانت عليه الظروف أثناء الإنتاج. بالإضافة إلى الكثافة، يمكن للمواد الكيميائية الفعلية الموجودة في الرغوة أن تغير الجوانب الحرجة مثل مدى صلابتها أو نعومتها عند الاستلقاء عليها. ومع ذلك، إذا كنت من النوع الذي يحرص على توفير المال مثلما أنا (من يستطيع لومنا؟)، فلا يوجد أي سبب ألا تنفق تلك الأموال الإضافية القليلة على رغوة آمنة ومحققة للشهادات لأن بعض أنواع المواد الكيميائية المختارة في منتجات الرغوة يجب تجنبها بكل تأكيد.

يعتمد جودة الرغوة بشكل كبير على العملية المستخدمة لصنعها. يمكن أن تنتهي الرغوة المصنوعة بشكل غير صحيح بوجود فروقات في الكثافة ومناطق ضعيفة ستؤثر على أدائها. يعتمد تصنيع الرغوة على خطوات التسخين والتبريد لضمان بنية محددة. علاوة على ذلك، تعتمد عوامل الجودة لمنتجات الرغوة بشكل كبير على نوع/الظروف/العلامة التجارية وما إلى ذلك من المواد الخام والمعدات المستخدمة أثناء الإنتاج.

للحصول على صيغة كثافة رغوة البولي يوريثان بشكل صحيح، من المهم أن يكون لديك قياسات دقيقة لكل من الوزن والحجم الخاص بالرغوة. قم بقياس كتلة الرغوة باستخدام ميزان دقيق عالي الدقة. سيضمن ذلك دقة أكبر في قياساتك. باستخدام مسطرة أو شريط قياس، يمكنك تحديد الطول والعرض والعمق الكامل لكتلة واحدة من الرغوة لحساب حجمها. عن طريق قياس هذا، ستحتاج إلى ضرب الأبعاد معًا وتحويلها إلى متر مكعب.

سيتعين عليك أيضًا أخذ أي فقاعات هواء قد تكون موجودة في الرغوة عند قياس حجمها. يمكن أن يؤثر هذا على حساب الكثافة بسبب هذه الفقاعات الهوائية الصغيرة ولكن القوية. ليس بشكل كبير، لأن الضغط سيؤدي إلى ضغط الرغوة وستكون الفقاعات الهوائية محسوبة ضد الحجم... أو استخدم شفط الفراغ لاستخراج أي هواء محبوس. تأكد أيضًا من استخدام القياسات الصحيحة، على سبيل المثال، مزج الأونصة الجرامية، أو الأرطال، أو الكيلوجرامات حسب الضرورة وأمتار مكعبة سائلة حيثما كانت مطلوبة أثناء حساب الكثافة (هذا ليس اختياريًا).

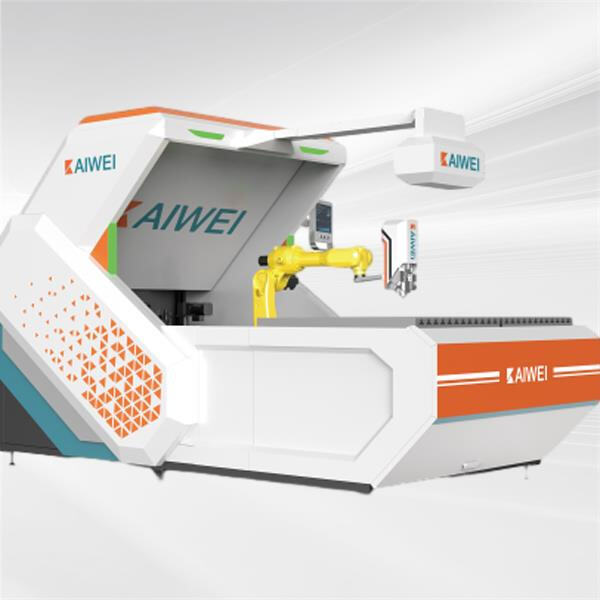

تستخدم آلاتنا تصميمًا متكاملًا، ما يجعلها أكثر كفاءة في تحضير تركيبة كثافة رغوة الـ PU؛ ولا تتطلب عمليات تشغيل احترافية، مما يقلل من عبء العمل الملقى على العمال؛ ويحسّن الإنتاجية. كما أن التشغيل سهل للغاية، ويمكن للمبتدئين البدء بالعمل خلال 30 دقيقة فقط، ما يبسّط خطوات الإجراء.

نقدم مساعدة شاملة بعد البيع في الموقع، بالإضافة إلى صيغة كثافة رغوة البولي يوريثين التي تحسن رضا العملاء. سواء كانت مشكلات تشخيص المعدات، الصيانة، أو متطلبات التدريب، سنقوم بجدولة موظفين للوصول إلى الموقع بسرعة لحل المشكلة بطريقة فعالة لضمان إنتاج وعمل سلس لعملائنا.

وبالنسبة لتركيبة كثافة رغوة الـ PU، فإن الغلاف المزود بوسادات إغلاق رغوية يمكنه أن يصل إلى درجة حماية IP67 أو حتى أعلى من ذلك. ولدينا أيضًا شهادات المطابقة الأوروبية (CE). وتتميز آلات كايوي الآلية الكاملة لإغلاق الرغوة بأنها ثلاثية المحاور، ومزودة بثمانية محركات مؤازرة وثماني علب تروس ومضختين بطول 4 أمتار.

لرأس الهجين KW-900 هناك ميزة براءة اختراع وطنية. لا حاجة لصيغة كثافة رغوة pu أو التحكم في الضغط (الظروف المناخية طوال العام تعيق قياسات متكررة لكثافة المواد الخام). قم بتغيير معلمات الشاشات مثل حجم الشاشة وكمية اللُّصوق المطلوبة لتلبية احتياجاتك.

حقوق النسخ © شركة شنغهاي كايوي للتكنولوجيا الذكية (المجموعة) المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية-المدونة