جهاز خلط الرغوة الـ PU هو جهاز خاص لخلط مادتين. المواد تُعرف باسم المكونات "A" و"B". المكون A غالبًا ما يكون سائلًا ينتج الرغوة والمكون B غاز يسمح لها بالتمدد. مزيج المادتين يؤدي إلى إنتاج الرغوة البوليميرية المعروفة باسم PU. الرغوة مفيدة لأنها يمكن تشكيلها إلى العديد من المنتجات.

عندما يكونون معًا في الجهاز، يتم إذابتهم بسرعة عالية ويتم خلطهم جيدًا. هذا أمر حاسم لأنه يضمن أن الرغوة تكون لها بنية جيدة وكذلك شعور بالفعل. تخرج المواد من فتحة صغيرة في النهاية تُسمى أيضًا بالفوهات، وبعد ذلك يُسكب الخليط على سطح مسطح. بمجرد وصولهم إلى السطح، سيتوسع الخليط ويبرد ليصبح رغوة نعرفها جميعًا.

تتوفر آلات خلط الرغوة البولي يوريثين (PU) بأحجام وأشكال وتصاميم مختلفة. لكن المهمة الأساسية لكل منها هي تخفيف المواد بالماء لتكوين الرغوة. وهي تُستخدم عادةً في المصانع التي تنتج الوسائد، ووسادات الجلوس، وحتى الأثاث. على الرغم من أن العملية قد تعمل بشكل مختلف قليلاً في كل آلة، إلا أنها جميعًا تساعد في إنشاء تلك الرغوة الرائعة التي نراها كلما تم استخدام هذه المكونات.

التحكم في الجودة مهم للغاية لتكوين الرغوة، حيث يجب "إغلاق" الرغوة (أي شفاؤها بمقدار معين) في كل مرة تنخفض فيها. يمكن أن تكون للمنتجات المصنوعة باستخدام هذا المادة مشاكل كبيرة إذا لم تتكون الرغوة بشكل متساوٍ عبر مجموعة من الظروف. على سبيل المثال، إذا كانت هناك رغوة صلبة جدًا أو ناعمة جدًا في السرير، فلن يكون مريحًا للنوم عليه. وهنا تأتي دور وحدات خلط رغوة PU للمساعدة.

يتأكدون من أن المكونين يتم خلطهما بنفس الطريقة تمامًا كما كان من المفترض دائمًا. وهذا يضمن أن الرغوة ستظل ذات جودة عالية باستمرار. هذا أمر أساسي بالنسبة للمصنعين لضمان قدرتهم على الثقة بالرغوة التي يصنعونها، مما يوفر عليهم أي مشاكل ناتجة عن استخدام رغوة منخفضة الجودة في منتجاتهم.

آلات خلط الرغوة PU تعيد تعريف طريقة تجميع الأشياء في المصانع. سابقًا، كان على العمال خلط الرغوة يدويًا. يتطلب هذا العملية الكثير من الوقت والجهد، مما يؤدي غالبًا إلى خلط غير موحد للرغوة. آلة خلط الرغوة PU هي الحل الذي يسمح للمصنع بالإنتاج بشكل أسرع وبطريقة متسقة، مرحباً بسرعة كانت مستحيلة من قبل.

لقد أحدث هذا فرقًا هائلًا للمصنعين في جوانب متعددة. ثانيًا، لقد جعل الرغوة تنتج بشكل أسرع لدرجة أن المصانع يمكنها إنتاج المزيد من المنتجات بتكلفة أقل. السبب الثاني هو أنه ساعد على تقليل الهدر بسبب انخفاض فرص إنتاج رغوة ذات جودة سيئة. وأهم شيء ربما هو أنه أعطى المصنعين حرية للتجربة مع أفكار جديدة وصيغ رغوية. وقد أدت بالتأكيد إلى تطوير بعض المنتجات الجديدة الرائعة التي يمكننا جميعًا الاستمتاع بها.

تم منح رؤوس KW-900 الهجينة براءات اختراع وطنية. ولا يتطلب الأمر قياس المواد الأولية، ولا التحكم في الضغوط (فإن تغير ظروف المناخ على مدار العام يعيق إجراء القياسات المتكررة لكثافة المواد الأولية). ويمكن تعديل آلة خلط رغوة البولي يوريثان (PU)، وأحجام شاشة النظام، ومقدار الغراء الخارج منها، وفقًا لاحتياجاتك.

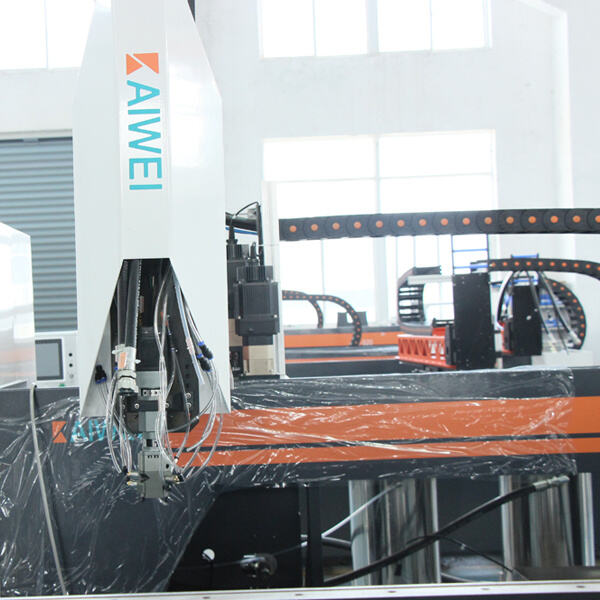

وبالنسبة لآلة خلط رغوة البولي يوريثان (PU)، يمكن أن تصل وسادة الختم بالرغوة إلى درجة حماية IP67 أو حتى أعلى من ذلك. كما أن لدينا شهادة CE. وتزود ماكينات كايوي للختم بالرغوة الكاملة الأتمتة بثلاثة محاور، وثمانية محركات مؤازرة، وثمانية مخفضات، وأربعة مضخات قياس.

تستخدم آلاتنا تصميمًا متكاملًا، ما يجعلها آلة أكثر كفاءة لخلط رغوة البولي يوريثان (PU)؛ ولا تتطلب عمليات احترافية، مما يقلل من عبء العمل الملقى على عاتق العمال؛ ويرفع من الإنتاجية. كما أن تشغيلها سهلٌ جدًّا، ويمكن للمبتدئين البدء باستخدامها خلال ٣٠ دقيقة فقط، مما يبسّط خطوات الإجراء.

نقدّم دعمًا شاملاً ما بعد البيع في الموقع، فضلاً عن تطبيق تعلُّم إلكتروني مبتكر خاص بآلات خلط رغوة البولي يوريثان (PU). وسنرسل موظفين إلى الموقع لصيانة المعدات أو تدريب المستخدمين أو استكشاف الأعطال وإصلاحها بشكلٍ فعّال وفي الوقت المناسب. وهذا يعني أن العملاء يمكنهم مواصلة التشغيل والعمل بشكلٍ طبيعي دون انقطاع.

حقوق النسخ © شركة شنغهاي كايوي للتكنولوجيا الذكية (المجموعة) المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية-المدونة