EN

EN

Avtomatik PU Qumush Gasket Chegarlangan Strips Yaratish Mashini, masalan, KW-530 modeli, toksi metall panel uchun gasket chegarlangan strips yaratish uchun maxsus tartiblangan. Poliuretan qumushidan foydalanib, ushbu mashin gasketni muammilsiz qo'llab-quvvatlaydi va turli omillarga qarshi effektiv chegarlanganlikni ta'minlaydi. Bu, toksi metall panel uchun aniqlik va davomiylikka ega bo'lgan gasket chegarlangan yechimlarni talab qiluvchi sanoatlar uchun ishlab chiqarish jarayonida effektivlik va ishonchni taklif qiladi.

Агар сиз қийматли глу бирịch машина ҳақида қидирсаңиз, онда Kaiweiдан KW-530 Пу макетлаш машина ва Янги Пу макетлаш машина шушманинг идеал арзисига эга бўлади. Ушбу инновацияли макетлаш ускунаси юксак сифатли материаллар билан ишланган ва юксак эффициентга эга.

Kaiwei To'liq avtomatik liyoz yig'ishchi ishlab chiqaruvchisi Avtomatik Foam Gasket mashini yangi Pu Gasket yasash mashini KW-530 mahsulotning keng tarqalganiga qarab, liyoz yig'ish uchun yaratilgan. U silicone, qaytib keladigan foam va epoxy kabi turli materiallarni boshqarishi mumkin. Ushbu shim mashini tez-tez, aniq yig'ish tizimi orqali ishlab chiqarish effektivligingizni oshirish va kasb-hunar xarajatlaringizni kamaytirishga yordam beradi.

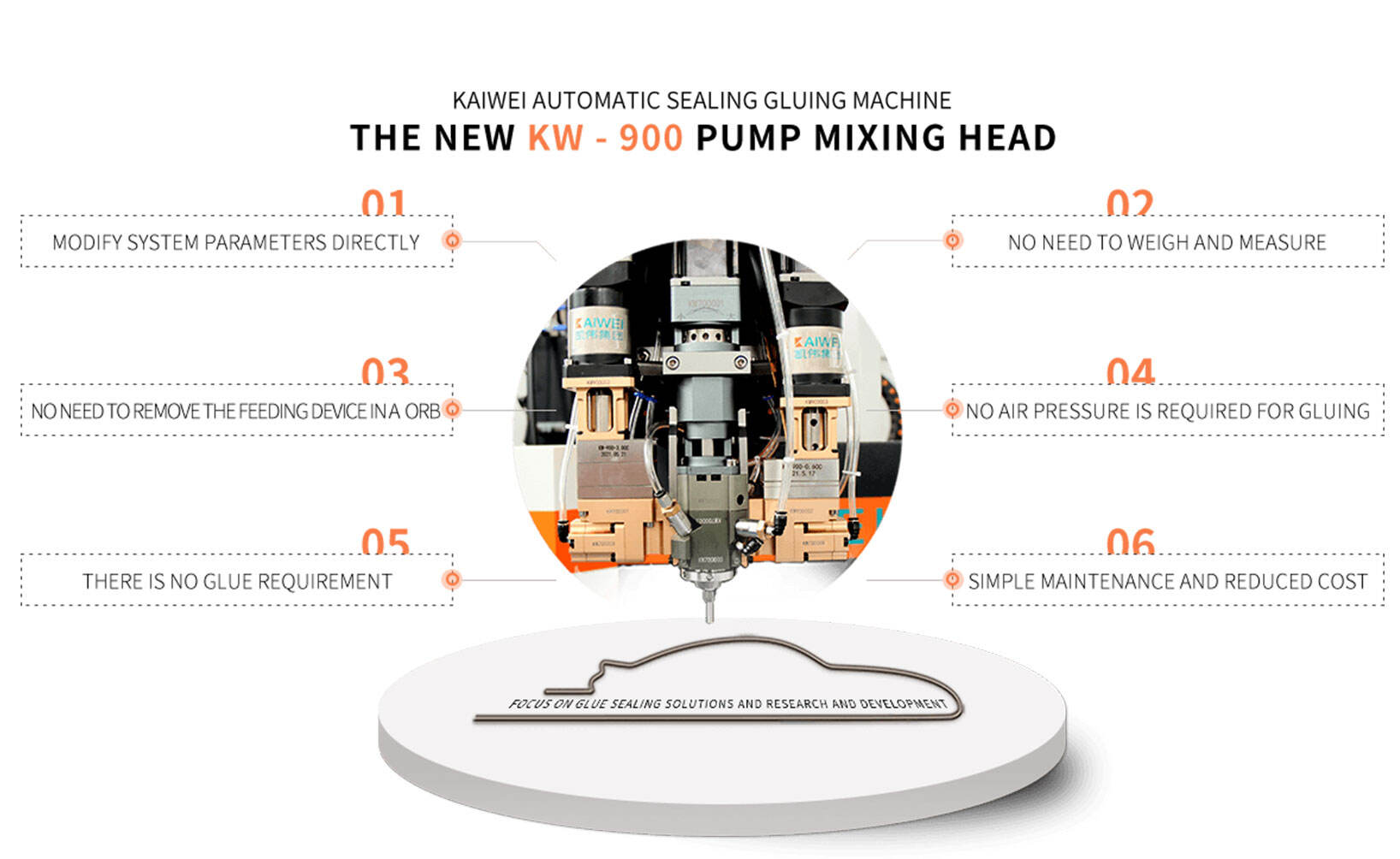

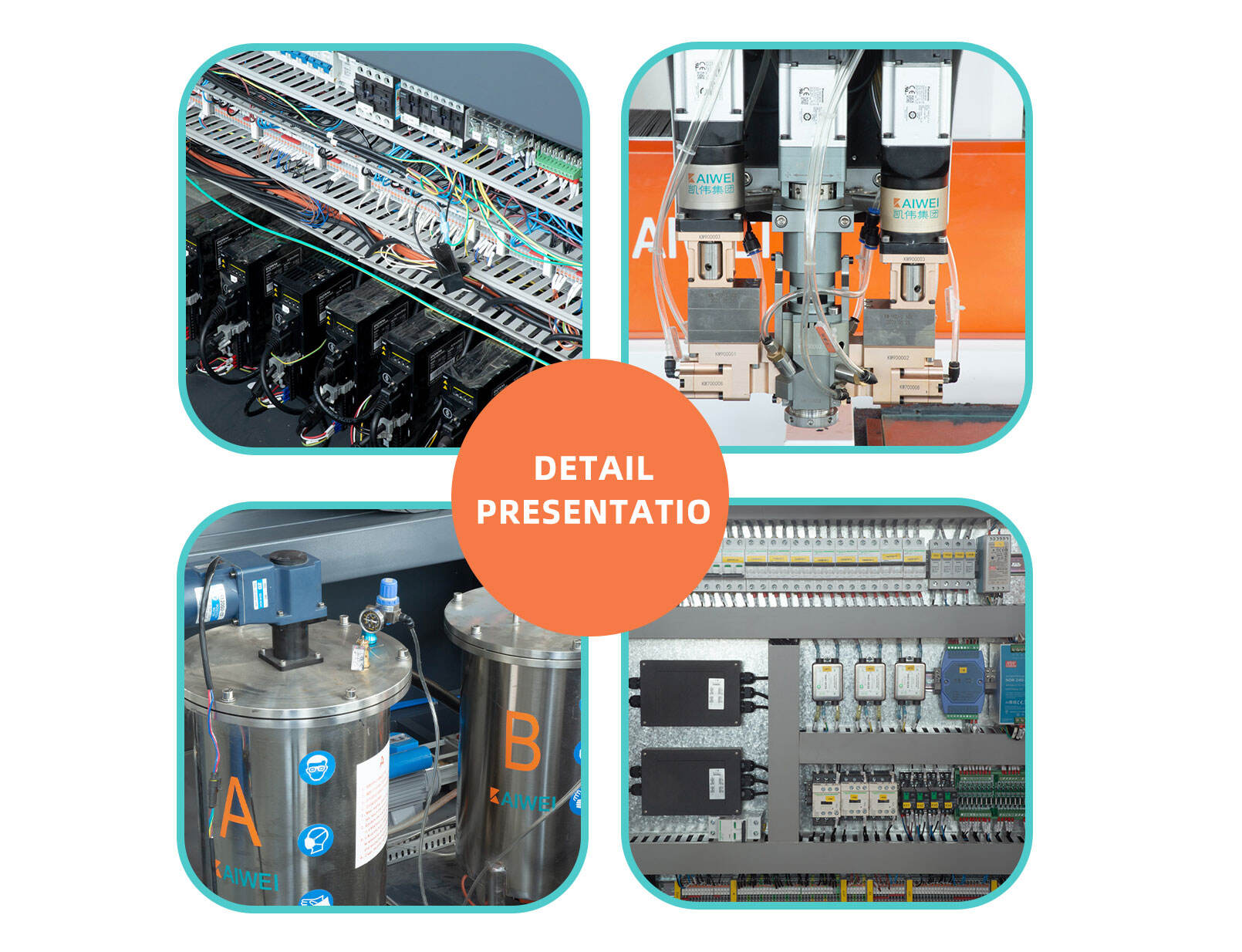

Bu Full-avtomatik Yopishqa Ma'shukchi Fabrikasi Avtomatik Pena Shim Masini Yangi Pu Shim Yaratingchi Masinasi KW-530 ning eng muhim xususiyatlari orasida soha darajasidagi boshqaruv tizimi keltirilishi mumkin. Qulay matnga o'tkazilgan interfeys bilan tashkil etilgan KW-530 foydalanuvchilarga ma'shukchining rejimini, tezligini va hajmini aniq belgilash imkonini beradi. Shuningdek, apparat bir necha ma'shuk rejimiga ega, masalan, bitta nuqtali chiziq, doira, yarim doira, narm yo'l va boshqalar. Bu uni juda ko'pfunksionallikka ega qiladi va siz ma'shuk shablonini dastlabki talablaringizga qarab shakllantirishingiz mumkin.

Kaiwei Full-avtomatik Yopishqa Ma'shukchi Fabrikasi Avtomatik Pena Shim Masini Yangi Pu Shim Yaratingchi Masinasi KW-530 umuman olganda juda davomli va uzun vaqt ishlatishga mo'mum. Uning robushtirgiy struktura va sifatli komponentlari bilan sotiladi, bu esa uning eng qiyin dastlabki vazifalarni oddiy ravishda bajarishini ta'minlaydi.

1. Sizning dozirlash tizimlaringiz qaysi sohalarda ishlatiladi?

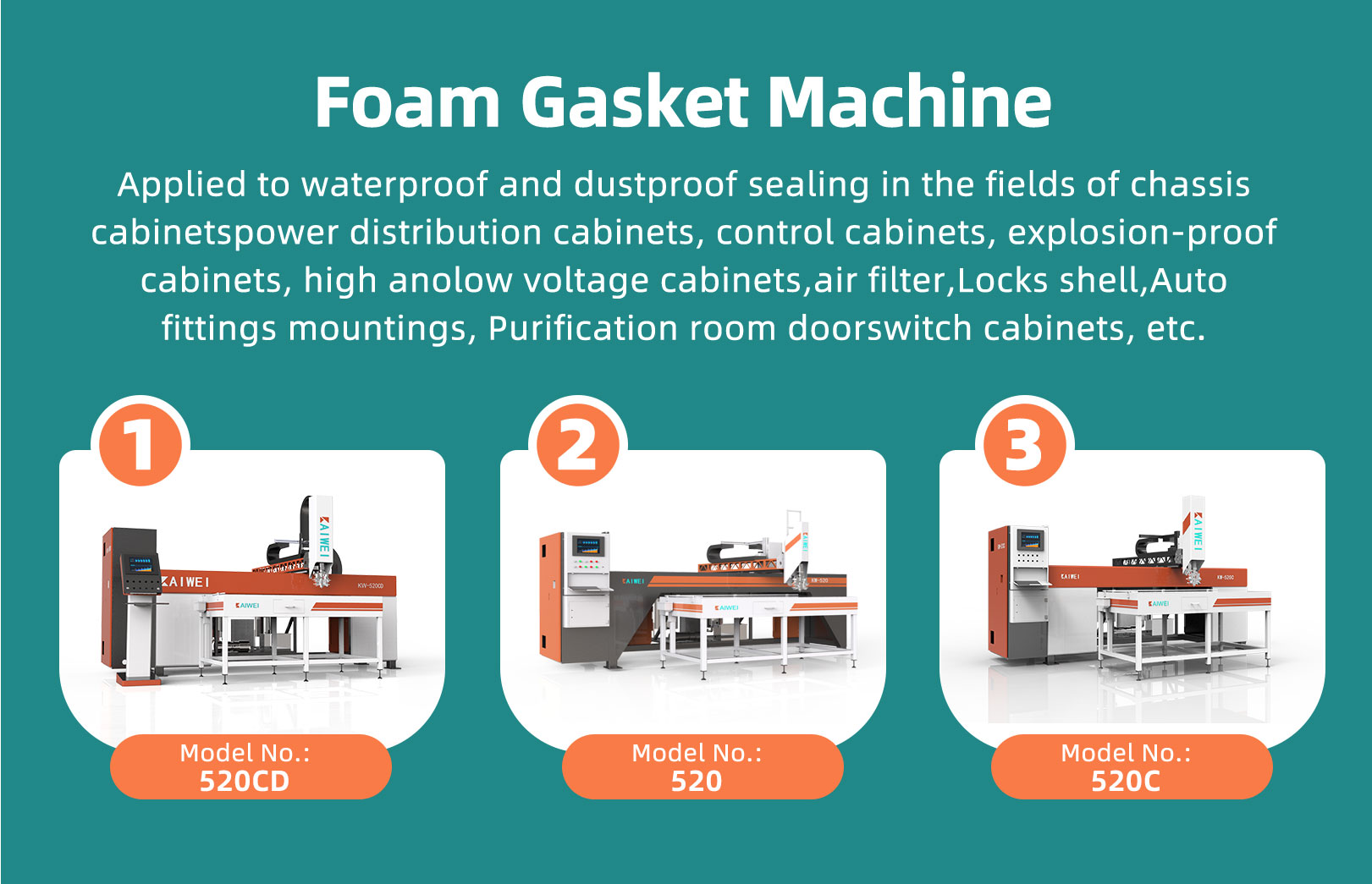

Bizning uskunamiz nazorat shkafchalari, elektr paneli, havo filtrlari, konditsioner eshiklari, shassi/shkafchalar, yangi energiya (masalan, batareyalar), avtomobillar, tozalash uskunalari, chiroqlar, mebel - qisqasi, aniq to'xtatish dozirlash yechimlarini talab qiluvchi har qanday sohada keng qo'llaniladi.

2. Uskunaning maksimal ish sohasi qanday?

Standart diapazon: 2250 × 1250 × 200 mm (U × K × B).

Maxsus yechimlar: Sizning ehtiyojlaringizga mos no-standart ish sohalarini va butun ishlab chiqarish liniyalarni loyihalab beramiz.

3. Uskuna qanday materialni dozirlaydi?

Ikki komponentli poliuretan (PU) peshlovchi klei (AB aralashtirish formulasi).

4. Yetkazib berish muddati qancha?

Standart uskuna: taxminan 7 ish kunida.

Loyiha/no-standart: taxminan 20 kun.

5. Siz qanday keyingi sotishlardan keyin yordam berasiz?

O'qitish: Bepul 3 kunlik bitta operator o'qitish.

Kafolat: 1 yillik mexanizm kafolati + doimiy texnik yordam.

Jihozlar nosozligining hal qilinish vaqti: 1 yildan keyin, agar jihozda nosozlik bo'lsa, KAIWEI fikr-mulohazasini olganidan keyin 1 soat ichida ta'mirlash kerak, agar sizga joyida xizmat ko'rsatish kerak bo'lsa, KAIWEI sizning mamlakatingizga 48 soat ichida yetib borishi kerak.

Keyingi savdo xodimlari: Kaiwei keyingi savdo bo'limi hamda hamkorlikdagi xizmat ko'rsatuvchi tashkilotlar 20 nafardan ortiq mutaxassislarga ega. Muntazam telefon qilish.

6. Jihozga ob-havo nazorati (masalan, sovutish) kerakmi?

Yo'q. U -15°C dan 35°C gacha (5°F dan 95°F gacha) ishlaydi.

7. Jihozlarni qanday tozalash kerak?

Suvli tozalash – ekologik toza, xavfsiz va arzon.

(Xitoyda ilk bor Kaiweining yangilik qilishidir!)

Copyright © Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. Barcha huquqlar himoyalangan - Maxfiylik siyosati-Blog