تسعى صناعة التصنيع باستمرار لتحسين عمليات الإنتاج، وزيادة الإنتاجية وجودة المنتج. عندما تحتاج إلى تصنيع الأشياء من الرغوة، فإن نصف المعركة يكون قد حُسم إذا كان اختيارك للمachinery مثاليًا. ولذلك يختار العديد من الشركات في قطاعات صناعية مختلفة آلات رغوة هينيكه لتلبية احتياجاتهم من إنتاج الرغوة.

هينيكه هي شركة تصنيع عالمية لمachines رغوة البولي يوريثان عالية الجودة، وهي ضرورية لبناء منزل كفؤ طاقويًا. تشتهر بتركيزها القوي على الجودة والأداء والمرونة، أصبحت هينيكه شريكًا موثوقًا في قطاعات السيارات، والبناء (eBAT)، والأثاث وكذلك سوق العزل.

استخدام أحدث التكنولوجيا هو ميزة بارزة أخرى لأجهزة تفريغ الهينيك. تأتي هذه الأجهزة بميزج ضغط عالٍ، قياس دقيق وتحكم أوتوماتيكي يجعلها مثالية لتقديم أداء وكفاءة عالميين فائقين.

تكنولوجيا الرغوة PUR-CSM من هينيكه، على سبيل المثال، تجمع بين جودة رغوية ممتازة وانبعاثات أقل بكثير. توفر هذه الشركة خيارًا ممتازًا للشركات التي تسعى إلى تحسين أثرها البيئي. بالإضافة إلى ذلك، توفر أنظمة رغوة البولي يوريثين啧من هينيكه عزلًا وتطبيقات أخرى بطريقة مرنة للغاية ولكنها فعالة من حيث التكلفة - مما يقلل من الهدر غير الضروري ويتيح تحقيق القدرة الإنتاجية بالكامل.

آلات صنع الرغوة من هينيكه مرنة بشكل لا يصدق أيضًا. لدى هينيكه الآلات والتكنولوجيات المناسبة لأي تطبيق، بدءًا من آلات قياس الضغط المنخفض (والمعروفة عمومًا باسم عملية البنتان) وصولاً إلى أنظمة تسليم الضغط العالي حيث تكون المنتجات ذات الطبقة الصوتية مطلوبة.

مثال على ذلك آلات خلط الضغط العالي من سلسلة Hennecke Streamline الموجهة لإنتاج الكتل، الألواح والصفائح لرغوة البولي يوريثين الصلبة أو المرنة. وعلى العكس، يتم استخدام PUR-CSM لإنتاج عازات عالية الجودة وكذلك سماعات وأغراض أخرى. بالإضافة إلى ذلك، يمكن تصميم خيارات مخصصة الحجم، الشكل ومعدل الإخراج في آلة تكوين الرغوة Hennecke وفقًا لاحتياجات الشركات الفردية من أهداف الإنتاج أيضًا.

الدقة والجودة هما عاملان رئيسيان في إنتاج الرغوة. ولذلك، استثمرت Hennecke بشكل كبير في البحث والتطوير لتمكين إنتاج بعض أكثر آلات معالجة الرغوة تقدمًا اليوم.

في التحكم الآلي المتقدم، الإلكترونيات قياس رقمية ورؤوس خلط بدقة عالية مصممة لتقليل الهدر وتُدمج في آلات الرغوة الخاصة بـ HenneckeOMET. عن طريق تطوير أنظمتها باستمرار، تمكّن Hennecke الشركات من التفوق على غيرها بتقديمها تقنية إنتاج رغوة حديثة.

هينيكه ماشينز للرغوة هو شريك أعمال استراتيجي جديد للشركات التي تسعى لتحسين عمليات إنتاج الرغوة وتطوير جودة المنتجات مع زيادة الكفاءة. وبفضل مزيج قوي من الابتكار، الجودة والأداء، هينيكه هي الرائدة عالميًا في تقديم تقنيات حديثة لتثبيت حلول PUR المخصصة بالكامل لتلبية مواصفات كل عمل تجاري فردي.

من البناء والعزل إلى الأثاث والسيارات، توفر هينيكه ماشينز للرغوة حلولاً موثوقة يمكن تعديلها بسهولة، مع تطبيقات تتراوح بين إنتاج الرغوة للمشاريع الصغيرة وحتى الشركات متعددة الجنسيات. إذن لماذا التأخير؟ تواصل مع هينيكه اليوم لتكتشف كيف يمكن لمعداتهم البولي يوريثانان أن ترفع قدرات الإنتاج لديك إلى مستويات جديدة!

رأس الهجين KW-900 محمي ببراءات اختراع وطنية. لا توجد قياسات للمواد الخام، ماكينة رغوة هينيشke (لا قياس ثابت للكثافة بسبب تغير المناخ الموسمي). يمكن ضبط كمية حجم اللصق والمعامِل الخاصة بالنظام في أي وقت، ولصق دقيق. المواد الخام لا تتغير، ولا يتغير نسبتها، ويتم قياس الوزن يدويًا قبل الاستخدام. لا حاجة لغرفة تبريد.

توفّر شركتنا خدمات ما بعد البيع الموسعة على الموقع وكذلك ماكينة رغوة هينيشke لتحسين تجربة العملاء وضمان الرضا. سنرسل العاملين إلى الموقع للصيانة أو التدريب أو حل المشكلات من أجل إصلاح المشكلة بسرعة وفي الوقت المناسب. وهذا يضمن أن معدات العملاء يمكنها الاستمرار في العمل والإنتاج بشكل طبيعي.

ليس من الضروري امتلاك جهاز تفريغ الهينيك؛ يقلل من العبء على العمال. من السهل استخدامه. بالنسبة للمبتدئين، يمكن البدء خلال 30 دقيقة.

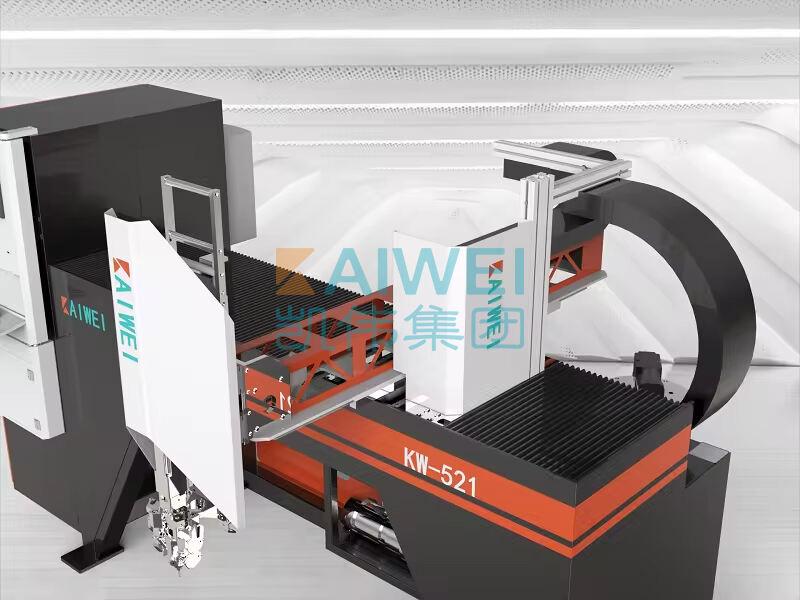

في اختبار مستوى الحماية يمكن أن تكون وسادات الإغلاق الرغوية IP67 أو أعلى. ولدينا أيضًا جهاز تفريغ الهينيك. آلات إغلاق الرغوة الأوتوماتيكية بالكامل من كايوي مجهزة بثلاث محاور، ثمانية محركات سيرفو، ثمانية مخفضات ومضخات طولها 4 أمتار.

حقوق النسخ © شركة شنغهاي كايوي للتكنولوجيا الذكية (المجموعة) المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية-مدونة