هل سبق لك أن تساءلت عن كيفية صنع الرغوة؟ الرغوة هي مادة ناعمة جدًا نستخدمها بطرق مختلفة يوميًا. على سبيل المثال، الوسائد الناعمة التي نستند عليها للجلوس لفترة والمقاعد المريحة في السيارات المصممة من الرغوة وحتى الألعاب يتم تطويرها منها. آلات الرغوة PU - نحن بحاجة إلى آلات لصنع هذه الرغوة، حيث يُعتبر PU اختصارًا لمادة البولي يوريثين، وهي نوع معين من المواد المستخدمة بشكل رئيسي في الرغوات. لقد ثورة آلة صنع الرغوة باستخدام آلات الرغوة PU طريقة إنتاج الرغوة حيث يمكنها إنتاج رغوة عالية الجودة بسهولة وسرعة كبيرة.

ما الذي تفعله آلة الرغوة الـ PU؟ في TERMS بسيطة، يتضمن خلط نوعين من السوائل - أحدهما يسمى الإيزوسيانات والآخر البوليول. يؤدي خلط هذين السائلين إلى تكون رغوة نتيجة للتفاعل الكيميائي. يمكن تشكيل الرغوة الناتجة إلى أي شكل أو حجم تقريبًا، مما يجعلها مثالية لعدد كبير من المنتجات. تُستخدم آلات الرغوة الـ PU في العديد من الصناعات، مثل صناعة الأثاث، وإنتاج قطع غيار السيارات، وتصنيع مواد البناء وغيرها.

ما هو مثير حول آلة رغوة البولي يوريثين، بالمناسبة، أنها يمكن تعديلها أو أن تكون ذات خصائص معينة للحصول على أنواع مختلفة من الرغوة. هناك أنواع مختلفة من الرغوة؛ بعض الرغوات مثل تلك الموضحة أعلاه ناعمة ومرنة، ممتازة للأرائك. بعض الرغوات الأخرى تكون صلبة وقوية مثل الموجودة في مقاعد السيارات. الشيء العظيم هو أن الآلة نفسها يمكن تكييفها لإنشاء رغوة من أي نوع مطلوب تقريبًا.

آلة الت forming تحت الضغط العالي هي مثال جيد على آلة رغوة البولي يوريثين الممتازة. تم تصميم الجهاز خصيصًا لإنشاء رغوة عالية وإعطائك نفس اللمسة في نفس الوقت. يتم خلط السوائل تحت ضغط عالٍ باستخدام جزء يُعرف باسم رأس الخلط الذي تم تصميمه خصيصًا لهذا الغرض. هذه الطريقة تنتج رغوة كثيفة ولديها قوة جيدة.

خصائص الآلات الجديدة متعددة ومتنوعة، أكثر بكثير مما هي عليه عند مقارنتها مع الأنواع القديمة. اليوم، ومع ذلك، تحتوي العديد من الآلات على تحكمات حاسوبية يمكن أن تصحح نفسها أثناء الإنتاج؛ وهي ميزة جد مفيدة أثناء عملية صنع الرغوة. هذا يجعلها مثالية لإجراء التعديلات لإنتاج الرغوة المطلوبة لتطبيق معين.

أكبر خصائص آلات رغوة البولي يوريثان في الوقت الحالي هي وظيفتها التلقائية. وهذا يعني أيضاً أن العمال في المصنع لا يحتاجون إلى القيام بجهد يدوي كبير أثناء إنتاج الرغوة. هذه الأتمتة توفر الكثير من الوقت وبالتالي المال، كما تقلل احتمال حدوث أخطاء أثناء التصنيع.

الجزء الأفضل هو أن آلات الرغوة الحديثة من نوع PU متاحة اليوم ويمكن أيضًا ضبطها لإنتاج النوع المطلوب من الرغوة بسهولة. هذا الضبط، بدوره، يجعل من السهل على مصانع التصنيع تغيير الإنتاج من منتج إلى آخر بسرعة وفعالية. على سبيل المثال، يمكن للمصنع الانتقال من دورة إنتاج إلى أخرى باستخدام نفس الآلة لإنتاج الرغوة المستخدمة في كراسي السيارات وفي المنتج النهائي مثل مقاعد النوم المرنة.

لا حاجة لعملية احترافية؛ ما يقلِّل العبء الواقع على العمال. وهي عبارة عن ماكينات رغوة بولي يوريثان (PU). ويمكن للمبتدئين البدء في التشغيل خلال ٣٠ دقيقة فقط.

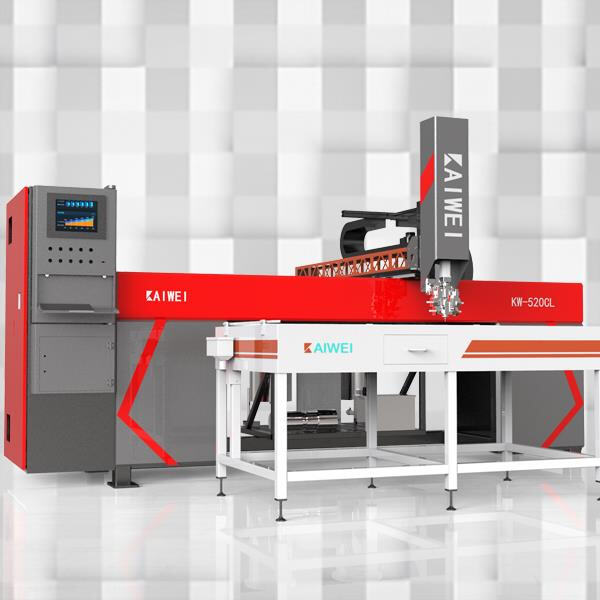

وبالنسبة لماكينات رغوة البولي يوريثان (PU)، فإن الغلاف المزوَّد بأقراص إغلاق رغوية قد يصل درجة حمايته إلى IP67 أو حتى أعلى. ولدينا أيضًا شهادات المطابقة الأوروبية (CE). وتتميَّز ماكينات كايوي الآلية بالكامل لإغلاق الرغوة بأنها ذات ثلاث محاور، وثمانية محركات مؤازرة، وثماني مخفضات، ومضخَّات بطول ٤ أمتار.

رأسات الهجين KW-900 هي ماكينات رغوة البولي يوريثان (PU) الحاصلة على براءة اختراع وطنية. ولا توجد حاجة لقياس المواد الخام، ولا تحكم في الضغط (ولا قياسٌ ثابت لكثافة المواد الخام بسبب التغيرات المناخية طوال العام). ويمكن تعديل كمية الغراء المُرشَّحة وكذلك معايير شاشات النظام في أي وقت لضمان دقة توزيع الغراء. كما لا تتغير المواد الخام المستخدمة، ولا يتغير نسبة خلطها، ولا توجد عملية وزن تُجرى آليًّا؛ بل يمكن إجراء الوزن يدويًّا قبل كل استخدام. ولا حاجة لتكييف الهواء في الغرفة.

نقدِّم دعمًا كاملًا ما بعد البيع في الموقع، فضلًا عن ماكينات رغوة البولي يوريثان (PU) التي تحسِّن من رضا العملاء. فإذا كانت المشكلة تتعلَّق باستكشاف الأعطال أو الصيانة أو متطلبات التدريب، فإننا نُنظِّم على الفور وصول الكوادر الفنية إلى الموقع لحل المشكلة بكفاءة، مما يضمن استمرارية الإنتاج وأداء عملائنا دون انقطاع.

حقوق النسخ © شركة شنغهاي كايوي للتكنولوجيا الذكية (المجموعة) المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية-المدونة