A glue dispense machine is one of the manufacturing equipment, which assists factories and small businesses to apply a liquid adhesive fasten over a product evenly. This machine is really useful and time-saving things for sure that glue applied in a uniform manner. But a glue dispenser rate may vary with respect to different conditions. The quality of the glue dispenser is one of the factors which has a significant effect on this price. Example:the new solid glue gun that technology is better, the material used to make it now become expensive than before.Then of course this costs a lot but after all, it saves your money.

The manufacturer of the machine is also a vital factor that must be kept in mind when considering glue dispensers. There are firms However, who concentrate on servicing high-quality but also higher-margin glue dispensers. On the flip side, there are companies that produce budget models (which still work but might not be high tech). Other things that can affect the cost of a glue dispenser include how well it actually functions, how long between repairs are needed and also now user friendly for workers with minimal training.

Businesses: are advised to compare the prices of different types of glue dispensers before making their purchase. Either by doing research online on what different models there are, or talking to other businesses about their experiences and recommendations. The differences one might find when comparing lists of prices can only be considered in light of the features that each model provides and an evaluation as to where these will serve them best. Something like a more expensive glue dispenser may lead to long term monetary savings due some additional features which are likely increase the amount of work it is doing for that higher price tag.

You could maybe buy a second hand glue dispenser. When a business like this upgrades to newer models they quite often sell their old glue dispensers, and you can usually snatch up these used machines at a steal. It is the best way to save money and also get high standard of things. Moreover, there are manufacturers that offer repaired and tested refurbished glue dispensers which may be a more affordable alternative than purchasing brand-new models.

Sure, a glue dispensing machine can be expensive to purchase; however its long-term value far exceeds any up-front costs. Faster, more even glue application can also save time and labor which translates into increased productivity from a judiciously placed investment in dispensing equipment. In addition, a glue dispenser can cut down on waste by ensuring that only small dabs of extra adhesive are employed. Businesses should also consider whether they would save money by investing in a glue dispenser. This dismissal will keep them away from proper calculation e.g., on how much glue they buy daily, the cost that goes in their current method of application and money saved with a dispensing m/c.

Before any business invests in such a tool they should consider several key factors to make it easier for them to get the most out of their glue dispensing machine. The most important part is to select the correct glue dispenser for one's requirement. In some cases, not every business requires a costly glue dispenser to perform their gluing processes effectively or non-costly models are sufficiently efficient for large scale operations. Accordingly, it is essential to know their business requirements for making perfect decision.

Moreover, the long-term maintenance costs associated with maintaining a glue dispenser should be accounted for; this can add another component to their budget. If you maintain the machine properly then it will work smoothly. And last but not least, employees need to be trained in properly using the glue dispenser. By learning this training, they can be more efficient and avoid any waste that happens, making the total savings not only high for them too.

The glue dispensing machine cost heads have an official patents in the United States. The heads do not measures raw materials and pressure controls is needed (climate conditions all year rounds make it impossible to measure the raw density of the material). Modify the screens parameters, size of the screen, amount of glue spit, to suit your needs.

It is not necessary to have a glue dispensing machine cost; reduces the workload for workers. It is easy to use. For newcomers, it is possible to start within 30 minutes.

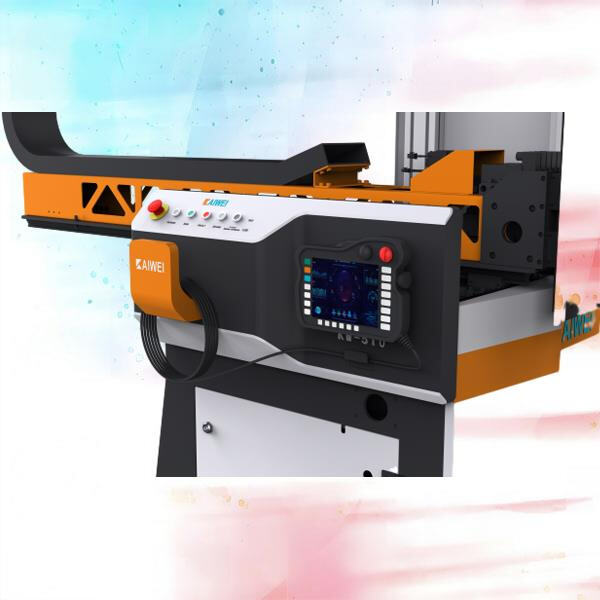

For glue dispensing machine cost that has foams sealing pad can reach IP67 or even greater. And we also have CE certificate. Kaiwei fully automatic foam sealing machines equipped with three axes, eight servo motors, 8 reducers four metering pumps.

We provide a comprehensive after-sales support on-site, as well as an innovative online learning app that glue dispensing machine cost. We'll send employees to the site for equipment maintenance, training, or troubleshooting to resolve issues in a timely way. This means that customers can continue to operate and operate normally.

Copyright © Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. All Rights Reserved - Privacy Policy - Blog