- 개요

- 추천 제품

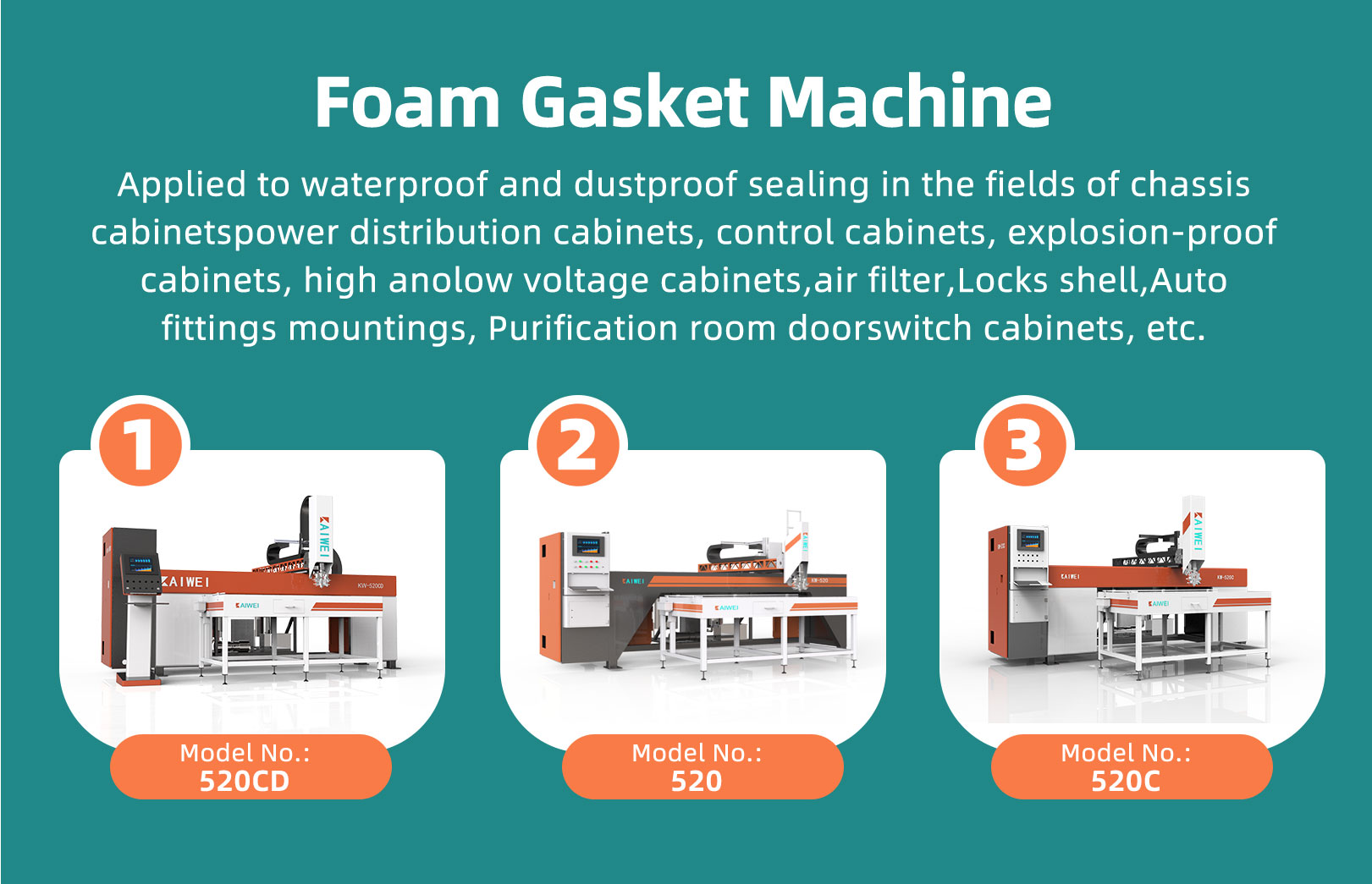

카이웨이 그룹은 각 고객이 독특하다는 것을 잘 알고 있으므로

다양한 맞춤형 외관을 통해 가장 적합한 것을 찾을 수 있도록 도와드립니다.

많은 선택 가운데에서 접착 기계를 찾아보세요.

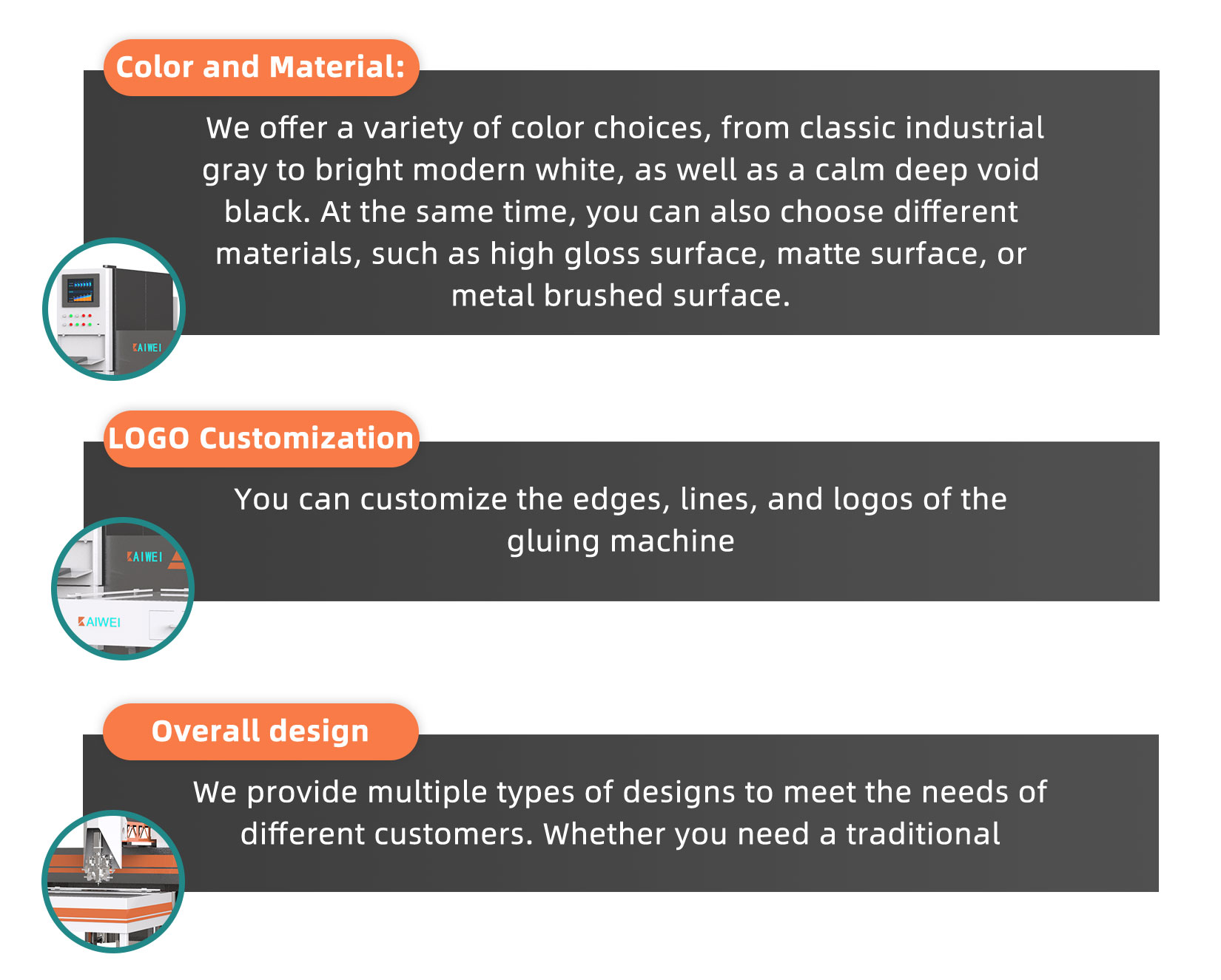

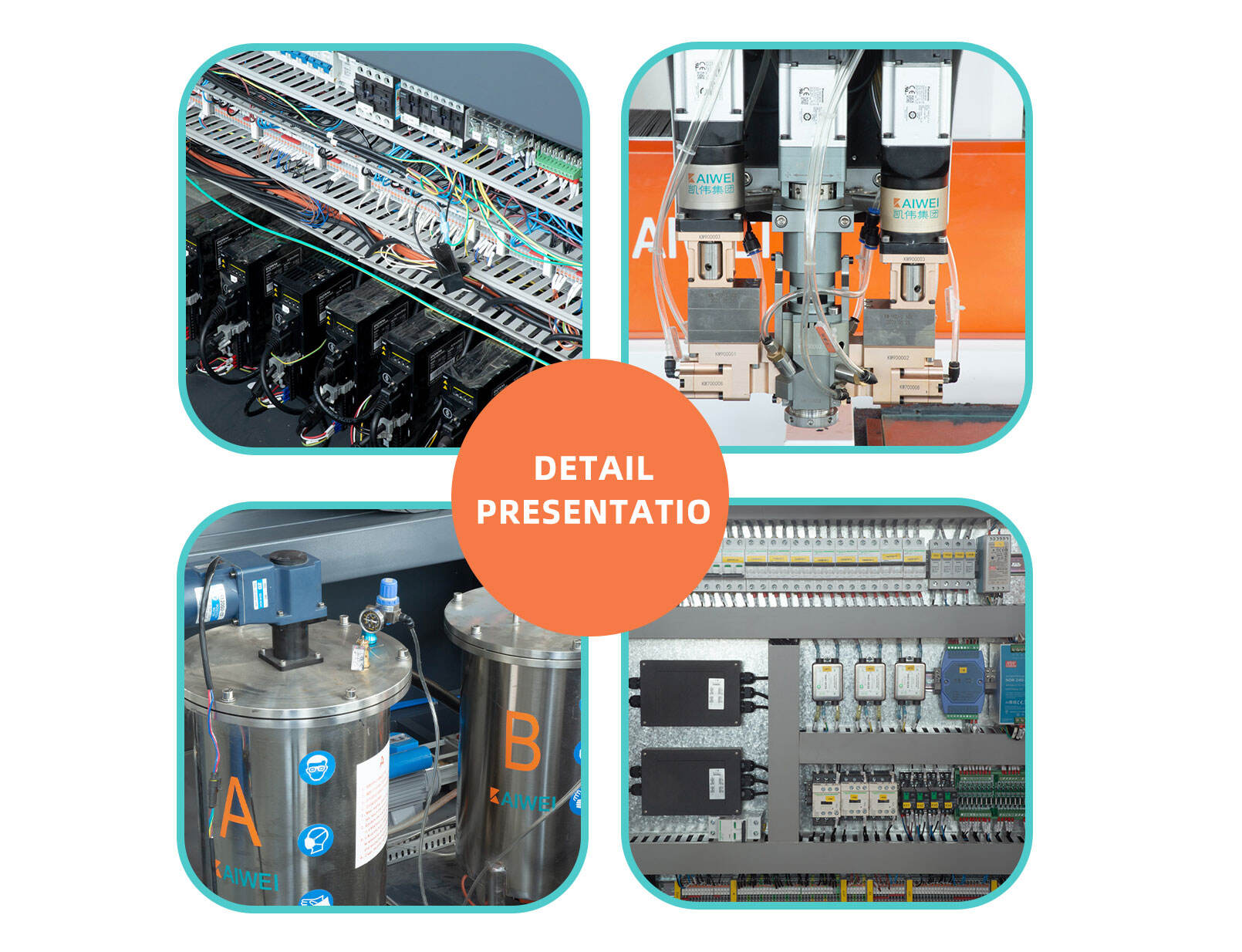

PU 가스켓 머신의 외관은 전문가에 의해 설계되었습니다.

단순한 색상과 패턴에 국한되지 않고

포괄적인 커스터마이징이 가능합니다. 재료 , 세부사항 ,

그리고 전체적으로 디자인으로 인해 수년간 큰 인기를 얻고 있습니다.

우리의 장점

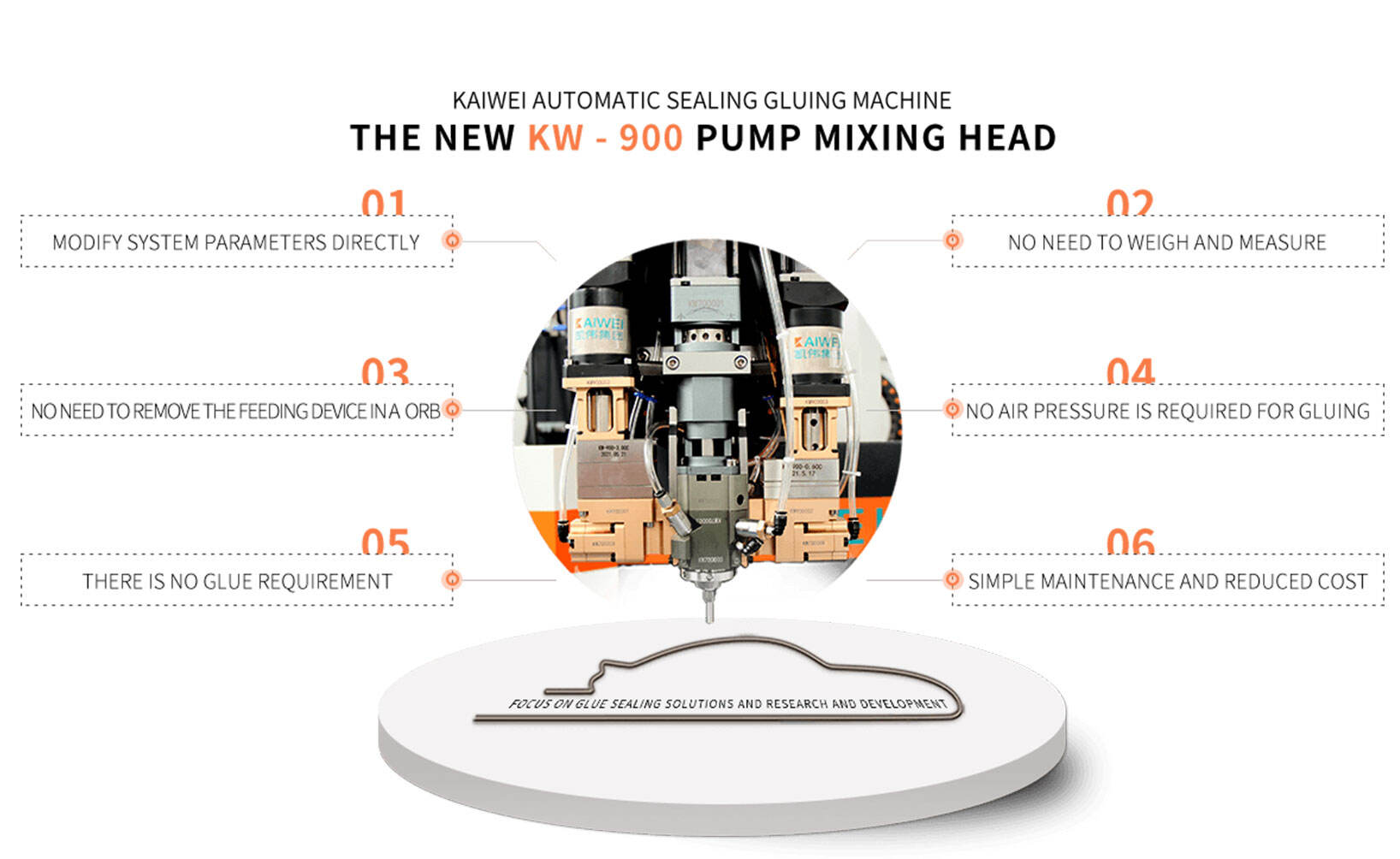

20년 동안 우리는 실링 접착제의 연구 및 생산에 집중해 왔습니다.

완전한 생산 체인과 종합적인 가공 공장이 있어

생산 품질을 통제할 수 있습니다.

애프터 서비스 현장 서비스 + 지속 가능한 서비스를 제공합니다.

온라인 디지털 교육 시스템

우리의 응용 프로그램

상하이 카이웨이 인텔리전트 테크놀로지 (그룹) 주식회사는 2004년에 설립되었으며 본사는 상하이에 있습니다. 고신기술 기업으로서, 카이웨이는 산업용 밀봉 시스템 및 로봇 폼 장비의 연구 개발과 생산에 특화되어 있습니다. 회사는 전문적인 연구 개발 기관과 완벽한 기술 혁신 체계를 가지고 있으며, 국내외 유명 기업들에게 자동화된 전기 솔루션을 제공합니다.

카이웨이는 "기술이 길잡이, 인재가 기반, 품질이 생명, 명성이 기초"라는 기업 이념을 견지하고 있습니다. 30명 이상의 기술 연구 개발 인력을 보유하고 있으며, 전체 R&D 수준은 중국 내 동종 업계에서 선두를 달리고 있습니다. 회사는 로봇 정량 발포기와 같은 기술 혁신을 선도하는 30건의 국가 특허를 취득했습니다. 자동 발포 봉인기는 전력, 유색 금속, 석탄, 석유, 화학, 제약, 군사 산업, 교통, 항만, 시설 건설, 자동화, 자동차, 전기 캐비닛, 공기 필터, 에어컨 정화 장치, 포장, 전자 부품, 조명, 신에너지 등 다양한 분야에서 널리 사용되고 있습니다.

카이웨이 제품은 ATEX, CCC, CE, INGRESS PROTECTION, 공장 방폭 인증 및 ISO9001-2000 국제 품질 체계 인증을 통과했습니다. 제품 품질은 고객들로부터 일치된 인정과 높은 평가를 받았습니다. 자동 발포 밀봉기기는 중국에서 잘 팔리고 있으며, 독일, 미국, 이탈리아, 베트남, 칠레, 러시아, 인도, 중동, 동남아시아, 남미 등 20개 이상의 국가와 지역에 수출되고 있습니다.

식물 강도

식물 강도

Q1: 귀사는 공장인가요, 무역 회사인가요? 우리는 전문 기계 제조업체입니다. 본사는 중국 상하이 청푸 지구에 있으며, 공장은 장쑤 수저우 지구에 위치하고 있습니다. 홍차오 공항/기차역에서 본사까지 차로 30분 거리이며, 언제든지 방문을 환영합니다.

Q2: 해외 에이전트가 있나요? 네, 우리의 고객은 호주, 뉴질랜드, 멕시코, 러시아, 인도, 말레이시아, 베트남, 태국, 아랍에미리트, 사우디아라비아 등 전 세계에 분포해 있습니다. 현재 우리는 인도, 호주, 사우디아라비아, 이집트 등 5곳 이상의 해외 에이전트를 보유하고 있으며, 계속해서 해외 시장을 확대하고 있습니다.

Q3: 귀하의 보증 조건은 무엇인가요? 1년 보증, 평생 기술 지원 제공. 보증 기간 내 무료 부품 제공(소모품 및 인위적 손상 제외). (일반적으로 추가 부품을 준비하며, 소모품은 기계와 함께 발송됩니다.)

Q4: 기계의 전력 전압이 제 공장의 전원과 호환됩니까? 전압은 귀하의 요구에 따라 맞춤 설정할 수 있습니다. 예를 들어, 인도에서는 415V, 50HZ, 3P; 미국에서는 230V, 60HZ, 3P입니다.

Q5: 기계를 어떻게 포장합니까? 기계는 표준 견고한 나무 상자로 포장됩니다. 기계 내부의 섬세한 부품은 스펀지나 폼과 같은 충격 흡수 재료로 채워집니다.

Q6: 기계가 양호한 상태로 도착하도록 어떻게 보장합니까? 우리 품질 관리 부서는 원자재에서 완제품까지 품질을 관리합니다. 기계가 완성되고 테스트될 때 검사 영상이나 사진을 보내드리며, 실시간 라이브 영상도 제공됩니다. 또한 공장 방문하여 기계를 확인하시길 환영합니다. 표준으로 양호한 포장을 제공합니다.

Q7: 기계를 어떻게 사용하나요? 우리 기계는 매우 쉽게 작동하며, 전체 세트로 배송되기 때문에 설치가 필요 없습니다. 또한 자세한 운영 매뉴얼, 엔지니어들의 시연 동영상, 그리고 Whatsapp, Wechat, Skype 등을 통한 원격 라이브 영상 가이드를 제공합니다. 공장 방문 후 직접 교육받으실 수도 있습니다.

Q8: 결제 조건은 무엇입니까? 30% TT를 예치금으로, 그리고 출하 전에 70%를 지불해 주세요.

Q9: 납기 시간은 얼마인가요? 대체로 말하면, 기계 세부 사항에 따라 약 30일입니다.

Q10: 귀하의 사후 서비스는 무엇인가요? 7*24 시간 서비스, 기계 작동 문제를 즉시 예의 바르게 해결해드립니다.Whatsapp, Wechat, Skype 등의 비디오 통화로 온라인으로 문제를 보여줄 수 있습니다.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

BN

BN

GU

GU

LA

LA

KK

KK

UZ

UZ