The Automatic PU Foam Gasket Sealing Strip Making Machine, such as the KW-530 model, is specifically engineered for producing gasket sealing strips for stainless steel panels. Utilizing polyurethane foam, this machine seamlessly applies gaskets to ensure effective sealing against various elements. It's a valuable asset for industries requiring precise and durable gasket sealing solutions for stainless steel panels, offering efficiency and reliability in production processes.

Then the Full-automatic Glue Dispenser Manufacturer Automatic Foam Gasket Machine New Pu Gasket Making Machine KW-530 from Kaiwei may be the perfect product for you personally in the event that you're in the marketplace looking for a glue premium-grade dispenser. This advanced gasket device is designed with top-quality materials and guarantees technology that are innovative and has a high efficiency.

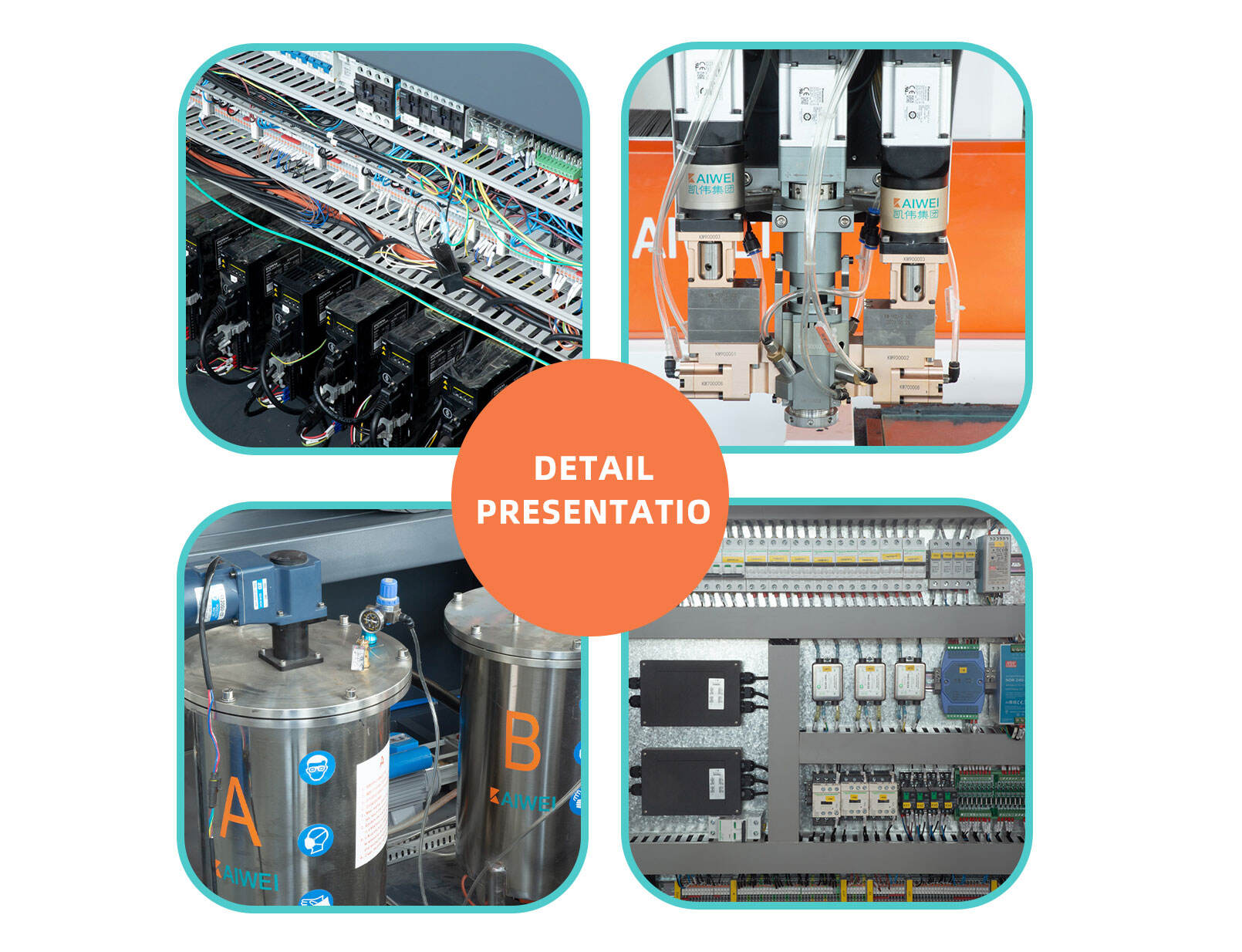

The Kaiwei Full-automatic Glue Dispenser Manufacturer Automatic Foam Gasket Machine New Pu Gasket Making Machine KW-530 is made to dispense glue making foam and PU gaskets for the product wide range of. It might handle a variety of materials, including silicone, rebound able foam, and epoxy. This gasket machine will help you to improve your production efficiency and reduce labor costs having its high-speed, high-precision dispensing system.

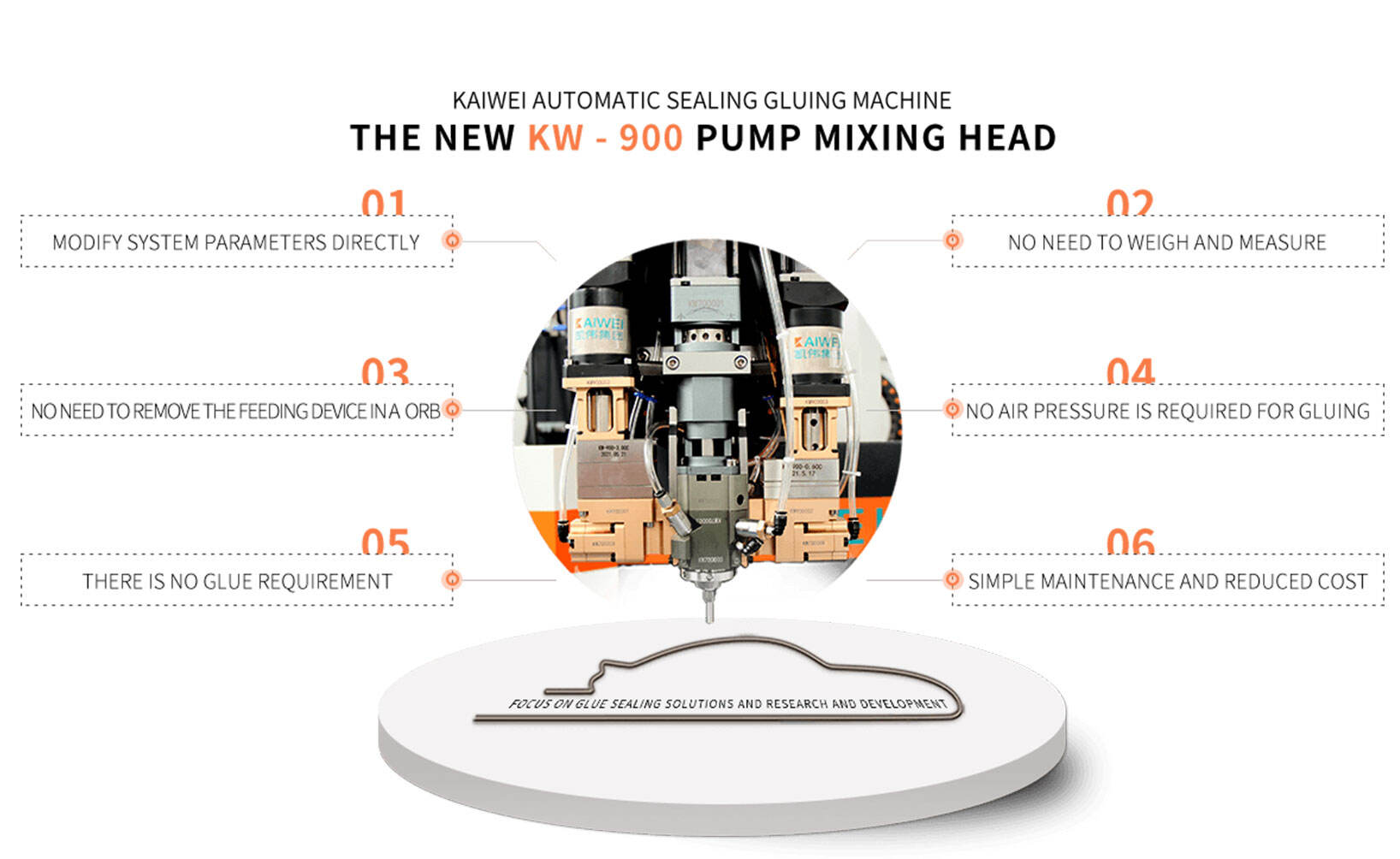

Among the standout highlights of this Full-automatic Glue Dispenser Manufacturer Automatic Foam Gasket Machine New Pu Gasket Making Machine KW-530 is its advanced control level system. Built with an easy-to touch-use interface, the KW-530 allows users to program the dispensing mode, speed, and volume exactly. Furthermore, the apparatus is sold with multiple dispensing modes such as single point line, circular, arc, irregular track, and more. This can make it extremely versatile, and you also can personalize the dispensing pattern relative to your application needs.

The Kaiwei Full-automatic Glue Dispenser Manufacturer Automatic Foam Gasket Machine New Pu Gasket Making Machine KW-530 normally very durable and may withstand very long hours of good use. The device is sold with a robust structure top-quality component, which means it would likely handle the toughest applications with ease.

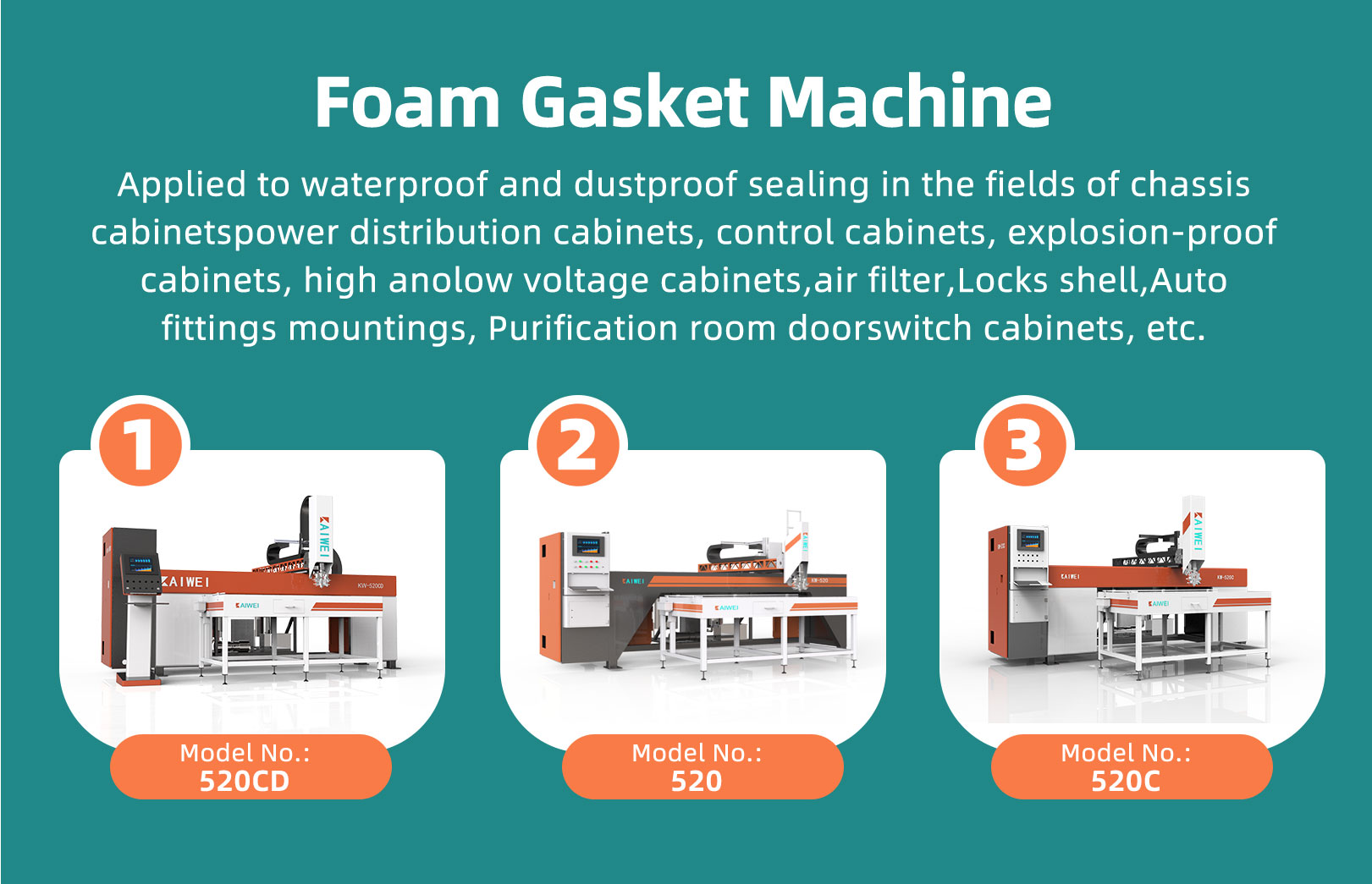

1. What industries are your dispensing systems used in?

Our equipment is widely used in control cabinets, electrical panels, air filters, AC doors, chassis/cabinets, new energy (e.g., batteries), automotive, purification equipment, lighting, packaging–essentially any industry requiring precision sealing dispensing solutions.

2. What’s the maximum working range of the equipment?

Standard Range: 2250 × 1250 × 200 mm (L × W × H).

Custom Solutions: We design non-standard working ranges and full production lines customize to your needs.

3. What material does the equipment dispense?

Two-component polyurethane (PU) foaming glue (AB mixed formula).

4. What’s the delivery lead time?

Standard equipment: about 7 working days.

Design/non-standard : about 20 days.

5.What after-sales support do you provide?

Training: Free 3-day one-to-one operator training.

Warranty: 1-year machine warranty + lifetime technical support.

Resolution time of equipment fault: within 1 year, if the equipment fault, KAIWEI needs to repair 1 hour after receiving it Feedback, if you need on-site service, KAIWEI needs to arrive your country with in 48 hours.

After-sales service personnel: Kaiwei after-sales service department and cooperative service providers have more than 20 senior professionals.Regular phone calls.

6. Does the equipment require climate control (e.g., AC)?

No. It operates in -15°C to 35°C (5°F to 95°F).

7. How is the equipment cleaned?

Water-based cleaning – eco-friendly, safe, and cost-efficient.

(Pioneered in China by Kaiwei!)

Copyright © Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. All Rights Reserved - Privacy Policy - Blog