Máquinas de injeção de espuma de poliuretano (PU) são verdadeiras revoluções quando se trata de manter os prédios quentes e vedados. Devido à sua capacidade de preencher lacunas e rachaduras, essas máquinas rapidamente se tornaram uma adição popular no trabalho de isolamento. Ela oferece maior durabilidade, é mais rápida e econômica em comparação com materiais convencionais, como fibra de vidro.

Agora, esses avanços chegam diretamente ao canteiro de obras com uma máquina portátil de injeção de espuma de PU que torna o isolamento e a vedação de maneira mais rápida e fácil. Hoje, neste artigo, vamos estudar diferentes tipos de máquinas portáteis de injeção de espuma de PU, seus custos e configurações. Mas antes de entrarmos nisso, vamos dar uma olhada mais detalhada no futuro do isolamento e vedação de ar.

Com o avanço da tecnologia de construção, também há uma urgência crescente por soluções melhores e mais verdes. A espuma de vidro pode ser cara, você pode ter que pagar alguém para instalá-la para você e, além disso, o material isolante de fibra de vidro gera muito pó, o que por sua vez pode causar alguns problemas de saúde. Por outro lado, a espuma de PU é uma aplicação promissora para isolamento e vedação em construções. A espuma de PU tem uma baixa condutividade térmica, o que mantém os prédios na temperatura desejada e funciona bem para conservação de energia. Ela também é impermeável, anti-mofo e oferece excelentes características de isolamento acústico para combater a poluição sonora. O uso de uma máquina de spray de espuma de PU pode proporcionar resultados de isolamento de maior desempenho e durabilidade para seus projetos de construção.

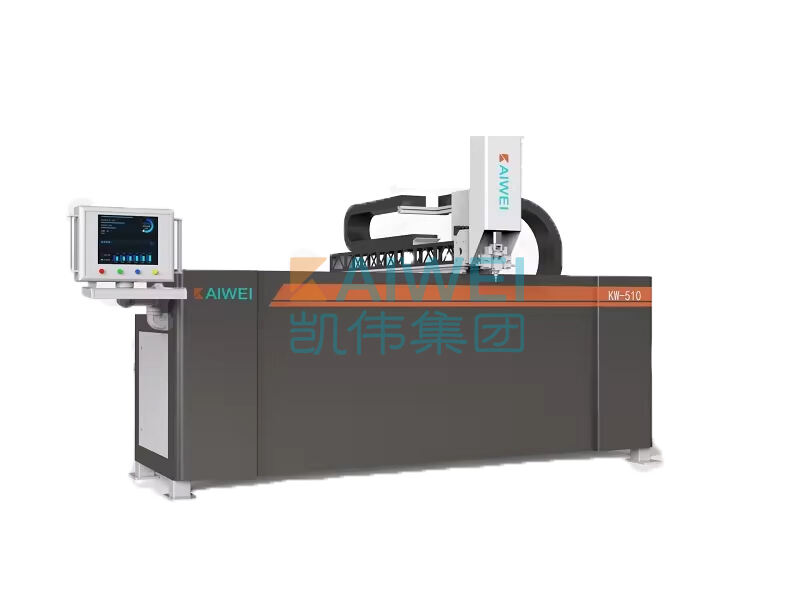

As melhores máquinas portáteis de injeção de espuma PU são feitas para serem eficientes, custo-benefício e fáceis de usar. Tamanho, peso e mobilidade são alguns dos fatores a considerar ao procurar uma unidade portátil adequada. Leve e móvel deve ser fácil de mover de um lugar de produção para outro, muito parecido com o que está na fotografia aqui. Além disso, é necessário que tenha potência suficiente para uma distribuição totalmente uniforme da espuma de isolamento, para que não fiquem buracos ou bolsas de ar no final.

A máquina perfeita de injeção de espuma PU portátil não deve levar em conta apenas seu custo, que deve ser acessível considerando os gastos com operação e manutenção. Ela deve ser econômica e consumir o mínimo de material bruto. Também deve ser fácil de usar, com pouca expertise técnica necessária. Os fabricantes geralmente fornecem manuais de instrução simples para instalação e processos operacionais, apoiados por treinamentos online ou presenciais.

Uma ampla gama de máquinas portáteis de injeção de espuma de PU está disponível para escolha no mercado. Confira os melhores modelos de Medidor de Umidade de acordo com suas características, vantagens e comparação de preços:-

Para o seu negócio de construção, uma máquina portátil de injeção de espuma de PU é um dos ativos mais valiosos a se ter, pois esse equipamento permitirá uma rápida e duradoura isolamento para seus projetos. O tamanho, peso, mobilidade e facilidade de uso são todos importantes ao escolher uma máquina para empregar. Escolha uma máquina que ofereça os recursos e benefícios certos para você isolar sua casa. Conclusão: o futuro do isolamento e vedação na construção são máquinas de injeção de espuma de PU. Elas são custo-benefício, eficientes - por isso, um número crescente de empresas de construção adotou essa tecnologia para projetos, agora usando tal máquina. Selecione a máquina perfeita para as necessidades do seu negócio e esteja pronto para aproveitar inúmeros benefícios com o isolamento de espuma de PU!

Não é necessário dispor de uma máquina portátil de injeção de espuma PU; isso reduz a carga de trabalho dos operários. É de fácil utilização. Para iniciantes, é possível começar a operar em até 30 minutos.

A nossa empresa oferece extensos serviços pós-venda no local, bem como uma máquina portátil de injeção de espuma PU, para melhorar a experiência do cliente e garantir sua satisfação. Enviaremos pessoal ao local para manutenção do equipamento, treinamento ou resolução de problemas, a fim de solucionar as ocorrências de forma rápida e oportuna. Isso garante que os equipamentos dos clientes possam continuar a funcionar e produzir normalmente.

Os seladores de espuma totalmente automáticos da Kaiwei são equipados com 3 eixos e 8 motores. Contam ainda com oito redutores, bem como uma máquina portátil de injeção de espuma PU.

As cabeças híbridas KW-900 são protegidas por uma patente nacional. As cabeças não exigem a medição de matérias-primas nem o controle de pressões (as condições climáticas ao longo do ano impedem medições frequentes da densidade das matérias-primas). Ajuste os parâmetros da tela, a máquina portátil de injeção de espuma PU e a quantidade de cola expelida para atender às suas necessidades.

Copyright © Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. Todos os direitos reservados - Política de Privacidade- Não.Blog