This machine has led to being used in different industries, various cleaning processes and promoting efficiency and environmental friendly methods. These Kaiwei Products convert liquid solutions into denser consistency foams that increase its coverage and their effectiveness while reducing waste materials. Precisely, it is necessary to consider: how foaming machines are revolutionizing industry; the scientific principles behind high-performance ones; sustainable trends in modern cleaning tools and equipment; how to choose a suitable machine for your business enterprise; and where foaming technology is used.

Foam making machines have played a major role in improving hygiene levels in different places. A lot of adhesive materials can be formulated, which easily stick on surfaces using little amount of solution hence less chemical exposure as well as water usage. Also this leads to cost saving and environmental responsibility at the same time. By use of such Kaiwei Auto Foam Sealing Machine within food processing factories, healthcare institutions or during car detailing, quick uniform cleansing takes place thereby ensuring much higher hygienic standards according to set rules.

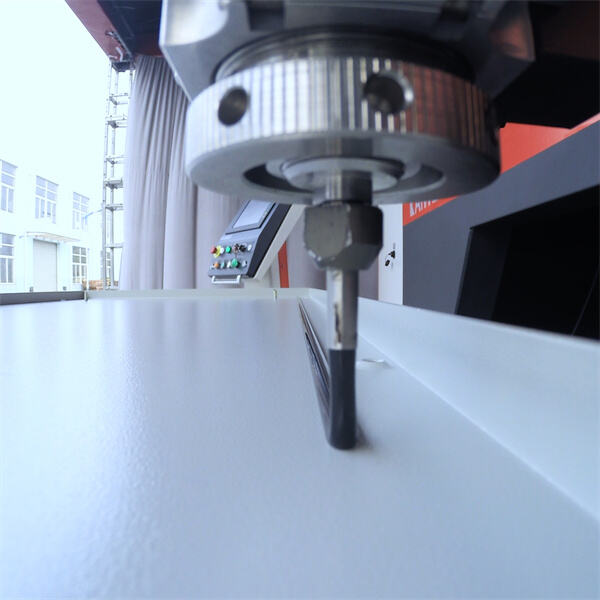

The designs for these high performance devices are characterized by complex combinations of mechanical stirring along with air introduction. They utilize precision pumps that suck detergent through then mixes it with compressed air within a special chamber provided for this purpose only. Controlled turbulence taking place inside this vessel initiates generation of millions upon millions microbubbles thereby forming a creamy solid foam similar to that produced by shaving cream. There are also those like Kaiwei Sealing Foam Glue Double which permit users control the density with regard this parameter thus making foam properties dependent on kind dirt surface dealing with whether it is light or heavy soil picked up should become clear when comparing performances across different apparatuses.

Contemporary foam producing equipment today reflects green practices. To this effect, majority of them have electric saving motors installed on the other hand others are made from recyclable substances that can be disposed of without affecting the biological balance of nature, while at the same time improved filtration systems using reduced amount of chemicals. Meanwhile to maintain both high cleaning speeds and minimal environmental impacts, some of them have friendly output modes. By subscribing to such Kaiwei Fittings; organizations are capable of reducing their carbon foot print while still looking up forward hygienic surroundings.

Certain factors must be considered when selecting a foam devices. You should know specific structures and levels. This is being assessed according to versatility, adjustability and compatibility with your preferred cleaning solutions by Kaiwei Auto Foam Sealing Machine. These prices influence durability and maintenance friendliness respectively in terms efficiency in future cost considerations. At the same time it is important to consider manufacturer’s support services like warranty, training and after sales service generally speaking. This has summed up everything which should be taken into consideration when choosing a machine that sufficiently caters for your business requirements.

In the protections level test the Foaming machine can be IP67 or even more. And we also have CE certificate. Kaiwei fully automated foams sealing machines adopts three axes, eight servo motors, 8 reducers and 4 meters.

Our company Foaming machine, but also an online application for teaching that will further improve customers experience and satisfaction. If it's equipment troubleshooting or maintenance needs, or even training needs we'll promptly schedules personnel on-site to resolves the issue efficiently to assures the smooth production and operation of customers.

The KW-900 hybrid heads are Foaming machine in the United States. The heads do not measures raw materials or pressure controls is required (climate conditions throughout the year make it impossible to measures the raw density of the material). Modify the parameters of the screens, such as the size of the screen, the amounts of glue spit, etc. to meet your requirements.

There is no need for a professional operation; Foaming machine. Simple to use. Beginners can begin in just 30 minutes.

The uses and adaptability of foaming machines has made them popular across different industries. In agriculture, it is being used for pest control and application of fertilizers to reduce wastes materials. They also ensure that the swimming pool area and outdoor furniture is kept cleaned in hotels. This ability allows them to clean complex car parts without damaging them. Moreover, foam dispensers in personal care products enable the soap or shampoo to be dispensed in measured quantities, thereby promoting cleanliness while reducing product usage. This large number of different uses shows the power of foam-making processes.

In conclusion, they have evolved from just being a normal cleaning methods into a powerful combination of efficiency and versatility. Kaiwei Sealing Foam Glue Double helps improve various industries’ use towards more efficient washing devices as well as ecological significance. By following closely recent developments on technological frontiers and tailoring their decisions accordingly companies can leverage this vast potential when they embrace foam technology alone thus revolutionizing their own operations.

Copyright © Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. All Rights Reserved - Privacy Policy - Blog