Words Monster words revolutionize, technology, precision, efficiency and productivity are very commonly used in factories. You may have heard this phrase before and thought, so what the heck does that even mean? How can they help us prototype great products faster and more easily? Let’s explore this together

It is one of the single important tools using in factories that are a Kaiwei industrial foaming machine. It is unique because it allows us to inject foam into various substances. This way, we can produce these materials stronger and lighter that eventually provides a longevity. For that we want to explore some fun filled facts about how a PU foam injection machine can be our dream product!

This will allow for cheaper and more versatile use of foams, to create products that simply work better than what is available today using foam. For instance, we can manufacture car parts with less weight in return using lesser fuel. Car repocise shu drive a car save gus and planet, face clean-uprecated 2020 In addition, we could build stronger and more energy-efficient buildings. And do with a PU foam injection machine we can produce more high quality products than ever

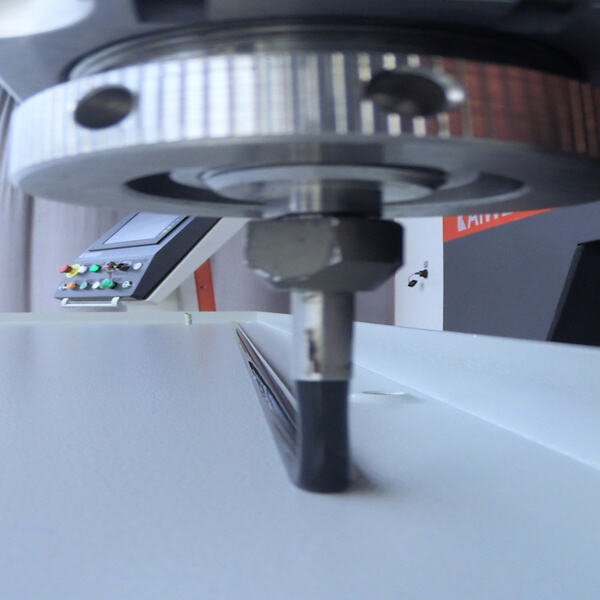

What Is the Precision of PU Foam Injection Machine The PU foam injection machine is very accurate. As a result, we can precisely manage the quantity of foam that is added to [a material] and exactly where it goes. This Kaiwei commercial foam machine allows us to design products that fit perfectly. Consider making an instance of a toy or auto part that is the ideal match!

The worst part about this machine is also that it is stupid efficient. Efficient means we use less of our product's material, time and energy waste when developing them. By cutting waste we save money; which matters a lot to businesses. Kaiwei foam equipment also allows us to create a lighter foot print on our planet by decreasing its use of resources.

Finally, the PU foam injection machine is versatile. This from production new is a unusable range of product that you could in turn use to create infinite items. Creating a foam for cars, buildings or furniture in seconds. The ultimate choice can vary depending upon the need of a particular factory but with this kind of flexibility in built it makes these cnc wire cutting machines one smart investment option for any factory.

Versatility: PU foam injection machine in all around process is very beneficial for any kind of the factory or industry which makes different products from confined repeat and pattern to varied angular designs forests. This allows us to meet a broad specter of customer requirements without having to invest in many different machines.

We provides comprehensive after-sales services on-site, and an Pu foam injection machine that increases customer satisfaction. When it comes to equipment troubleshooting or maintenance needs, or even training needs we'll promptly schedules personnel to be on site to resolve the issues in a timely manner to assure the smooth production and performances of our customers.

Kaiwei's fully automatic foam sealers is fitted with 3 axes and 8 motors. It also comes with eight reducers as well as a Pu foam injection machine.

It is not necessary to have a Pu foam injection machine; reduces the workload for workers. It is easy to use. For newcomers, it is possible to start within 30 minutes.

The Pu foam injection machine heads have an official patents in the United States. The heads do not measures raw materials and pressure controls is needed (climate conditions all year rounds make it impossible to measure the raw density of the material). Modify the screens parameters, size of the screen, amount of glue spit, to suit your needs.

Copyright © Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. All Rights Reserved - Privacy Policy - Blog