Over the last decade, major changes have occurred in the insulation industry thanks to new technological feats. Among those crucial advancements that are causing this modification is the hydraulic spray machine. Homeowners use these machines increasingly and even the builders also prefer to get their insulation work done from cannon machines due to their efficiency, indeed.

Hydraulic spray foam machine is a hydraulic driven pump for the spraying of polyurethane materials. This forms a strong and weather resistant insulation layer which regulates the temperature of building thereby in turn, but not exclusively; lowers heat lose leading to lower energy required. This technological revolution has turned the insulation sector on its head in a way that is transforming how builders and homeowners alike carry out their rubber spray insulation projects, for the better.

Increased Effectiveness: Hydraulic spray foam machines are faster and more efficient when it comes to an insulation application than other traditional methods. This equipment enables to finish work so quickly and can cover a large portion of it, which won't require many labours involved in the project.

Providing Exceptional Longevity: The polyurethane foam insulation that is sprayed by pressurized hydraulic machines stands the test of time. It is moisture and pests resistant, thus making it an amazingly durable material that can last forever without having to go through the nuisance of frequent renovations.

For example, a hydraulic spray foam machine can be more costly than other methods of insulating in the beginning; however over time you are going to save money. This efficiency and its longevity result in cost savings for both homeowners - less maintenance, repair or energy costs over time - as well as builders.

Better Indoor Air Quality: Hydraulic spray foam insulation leaves no cracks or gaps in your home, so fresh air doesn't come in from the outside and pollutants, allergens and external noise can be reduced. This results in a healthier living space with improved indoor-air quality.

Graco Reactor E-20: For commercial as well residential projects the machine suited with applications provides custom maximum advanced control technology in foam output, is lightweight and versatile.

TAF T-112: Used in low-to-mid-output projects, the highest rated transfer pump delivering only 8 pounds of polyurethane foam insulation per minute ideal for residential and commercial applications Web masters or forum owners copy our article to yours.

Gama Spraying Equipment Classic: With a high- quality two-piston pump, unique vulcanised mixing system and innovative control center this machine can run 24/7 without overheating which is ideal for large insulation works.

Titan SprayTech G30: Designed with versatility and ease of use in mind, the Titan model is a mobile lighter version ideal for small projects that allows operators to maneuver quickly which helps it become one of top choices among residential users.

IPM Drum Mixers: A portable drum mixer that mixes polyurethane foam on-site, for both small and large insulation contracting projects.

Getting The Best Choice Of Hydraulic Spray Foam Machine For Your Insulation JobsThe right hydraulic spray foam machine for your insulation projects can be chosen based on a number of factors, including the size of project, how much output you need and what's in your budget. Before you decide one way or another, do your homework and if necessary consult with experienced people on the topic.

Hydraulic Spray Foam Machines are green energy solutions for homeowners and businesses looking to reduce their carbon footprint as well. The machines also come with energy saving and insulation features that, when combined are demonstrated to reduce your costs by 40% which undoubtedly saves you the tremendous amount of money along a significantly smaller carbon footprint.

In summary Hydraulic spray foam Machines are changing the face of insulation with their cost-effective, long-lasting and efficient solution. Since hydraulic spray foam machines are capable of reducing air leakage, lowering energy usage and improving indoor living conditions by appropriately insulating spaces, it offers a more sustainable insulation solution that will last.

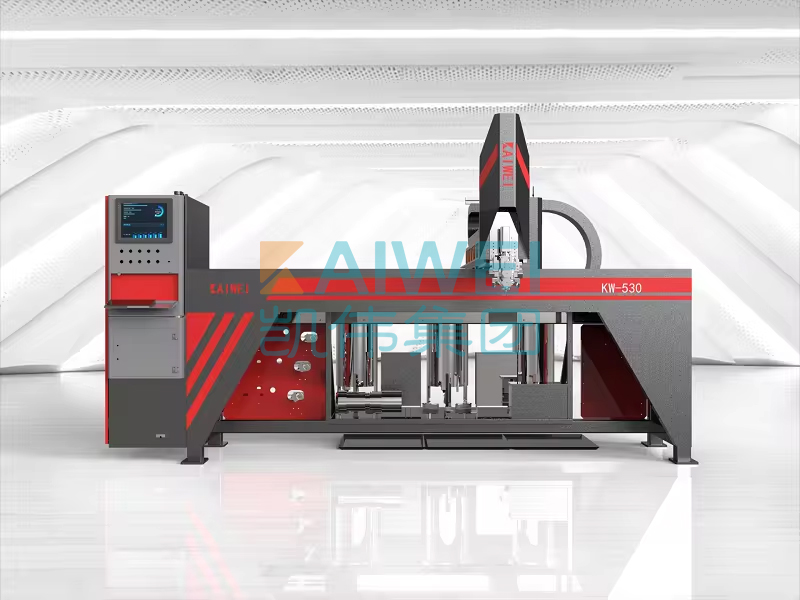

Kaiwei's completely automated foam sealers is hydraulic spray foam machine and 8 motors. It also comes with 8 reducers and 4 metering pumps.

The KW-900 hybrid head is protected by patents for nationals inventions. No measurements raw materials, no pressures control (no regular measurement of raw material density because of seasonal climate changes). The quantity of the size of glue spit as well as the system's screens parameters can be changed at any time to hydraulic spray foam machine. The raw materials aren't changed, the proportions of raw materials not changed, and there is no weighing measurement should be manually weighed prior to every uses. No requirement for a cooling rooms.

There is no need for a professional operation; hydraulic spray foam machine. Easy to operate. For newcomers, it is possible to start in less than 30 minutes.

Our company is hydraulic spray foam machine as well as an innovative online educational apps to enhance customer satisfaction and experience. We'll sends employees to the site for training, maintenance or troubleshooting to solve the issues in a prompt way. This will ensure that our customers are able to continue operating and continue to produces as normal.

Copyright © Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. All Rights Reserved - Privacy Policy - Blog