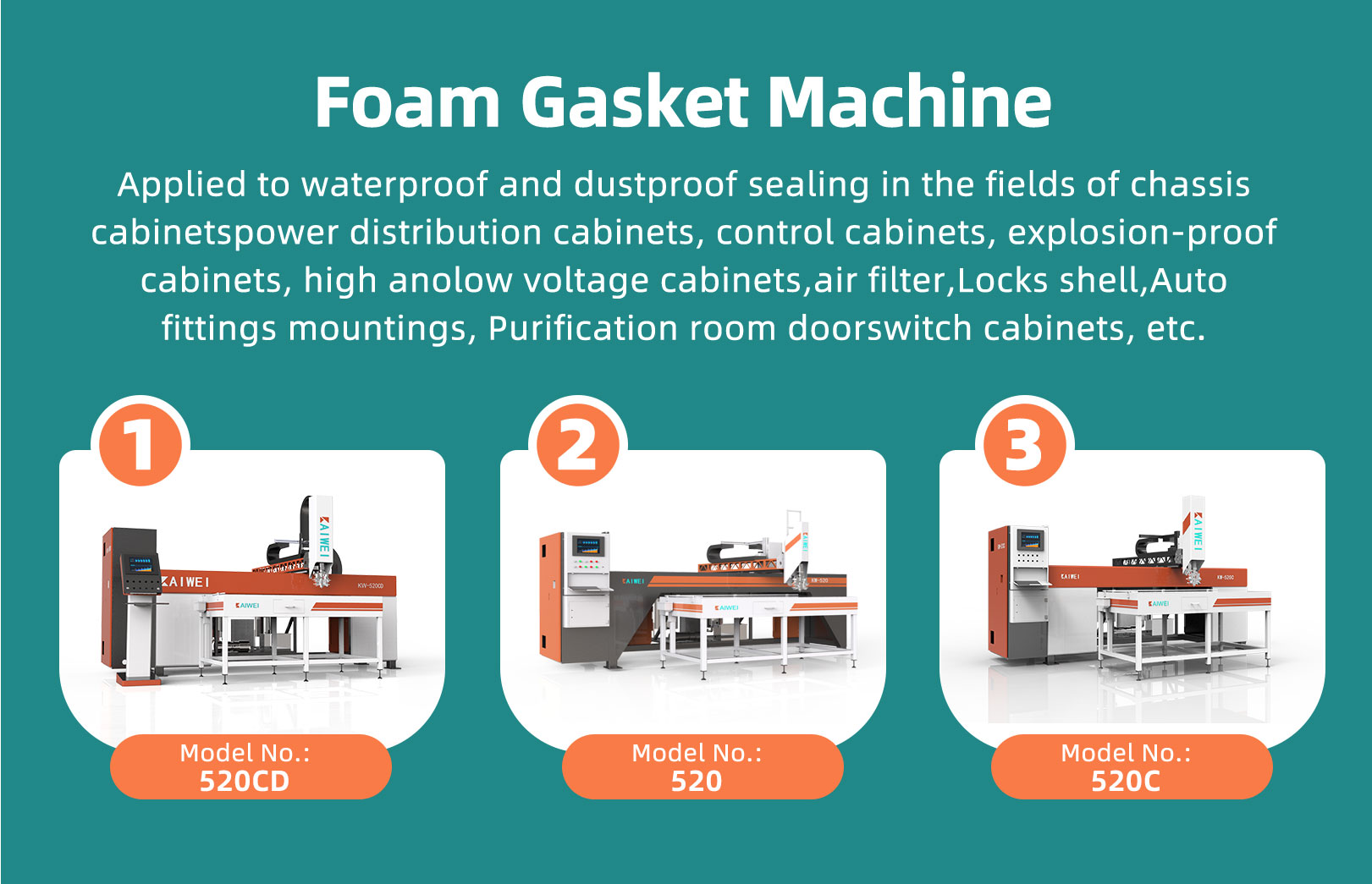

KW-520 Automatic Foam Sealing Machine Form-In-Place Gasket Dispensing Pu Gasket Dispensing Machine

- Overview

- Recommended Products

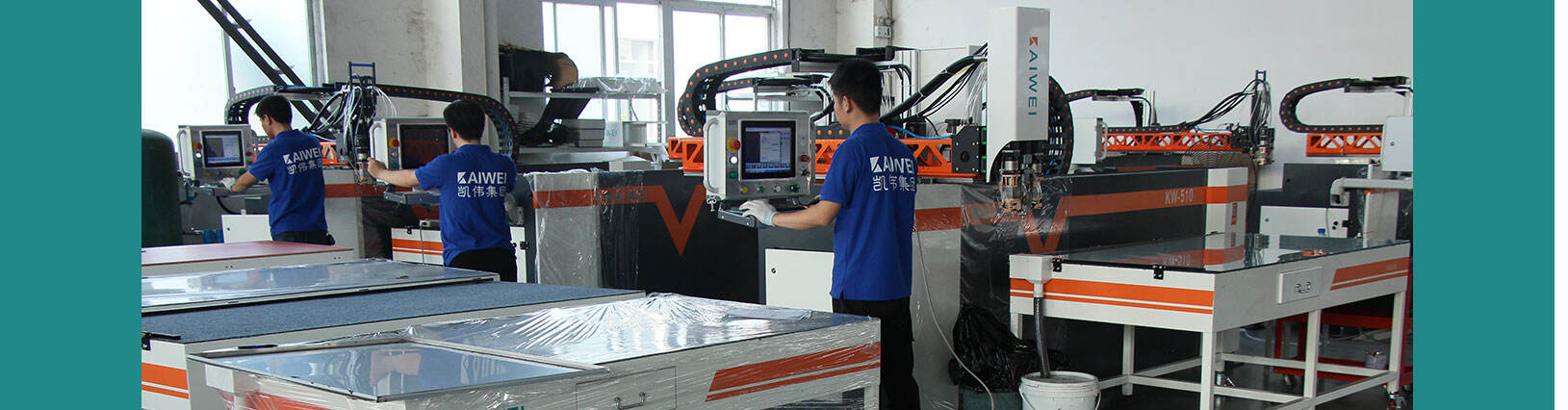

Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. was founded in 2004 and headquartered in Shanghai. As a high-tech enterprise, Kaiwei specialized in R & D and production of industrial sealing system and robot foaming equipment. The company has professional R & D institutions, perfect technical innovation system, and provides automation electrical solutions for well-known enterprises at home and abroad.

Q1: Are you a factory or trading Company?We are a professional machines manufacturer. Our headquarter is in Qingpu district, Shanghai, CN. Our factory located in Suzhou district, Jiangsu, CN. It only takes 30 mins from Hongqiao airport/train station to our headquarter, you are always welcome to visit us.

Our engineers are also available to serve on abroad.

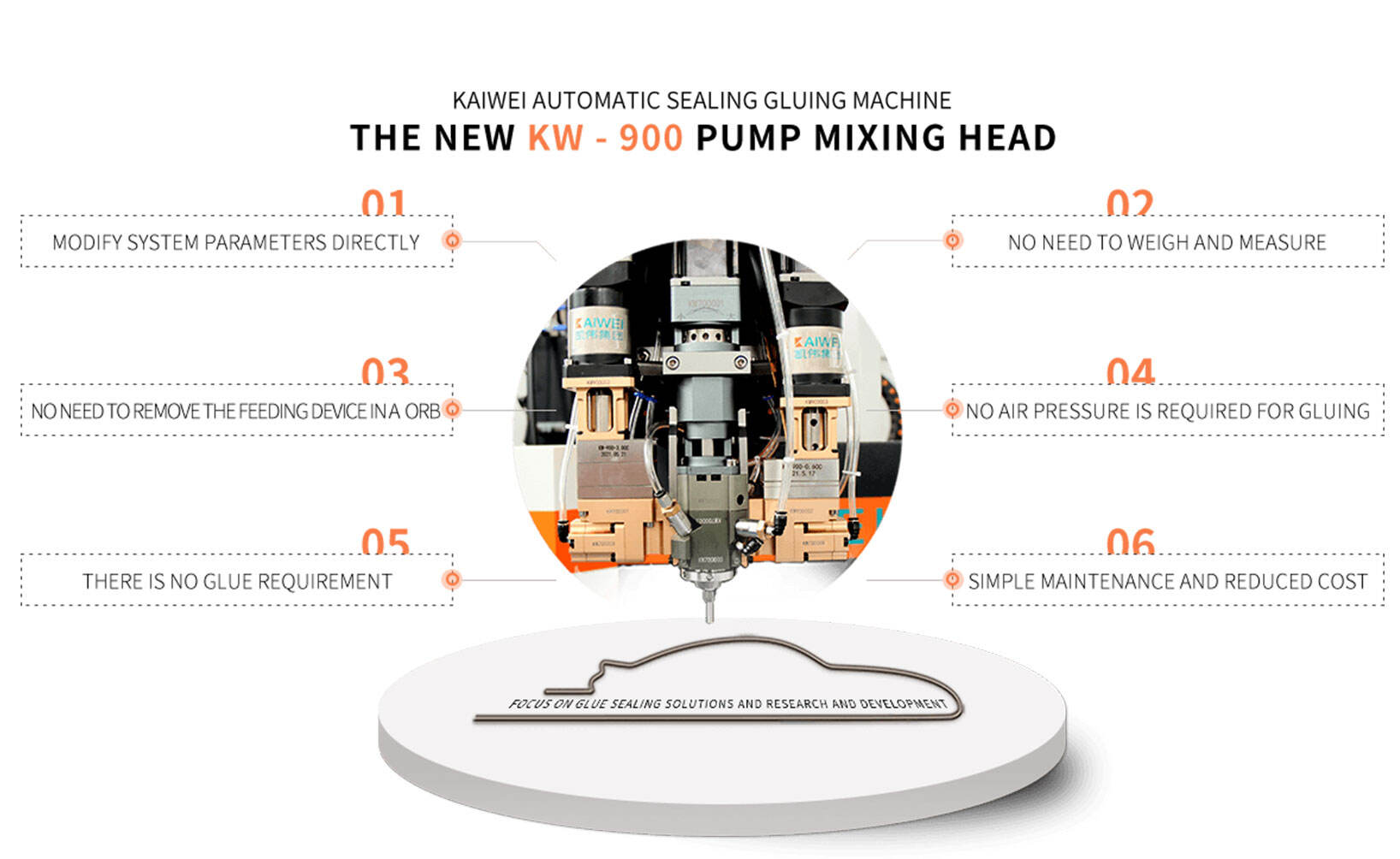

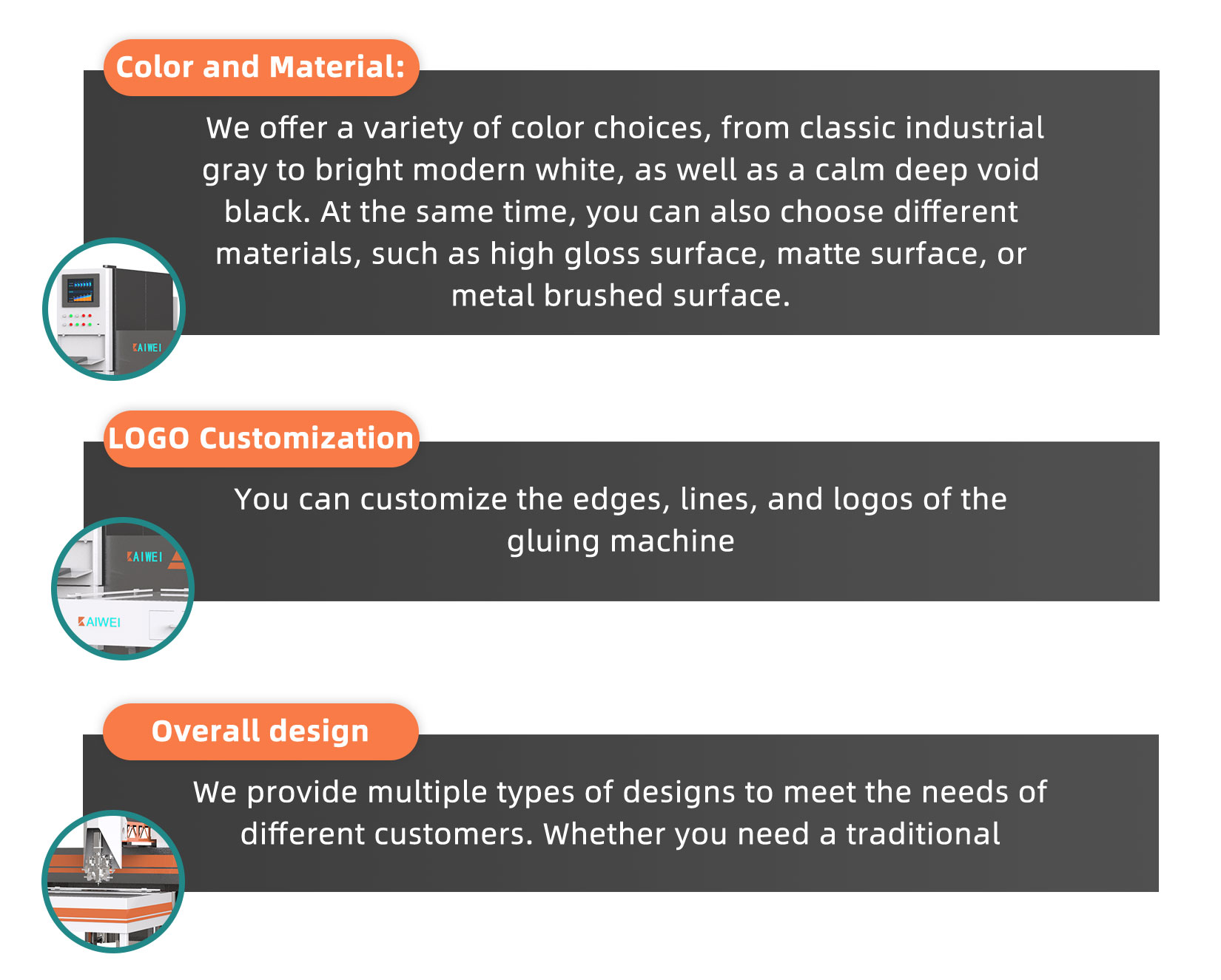

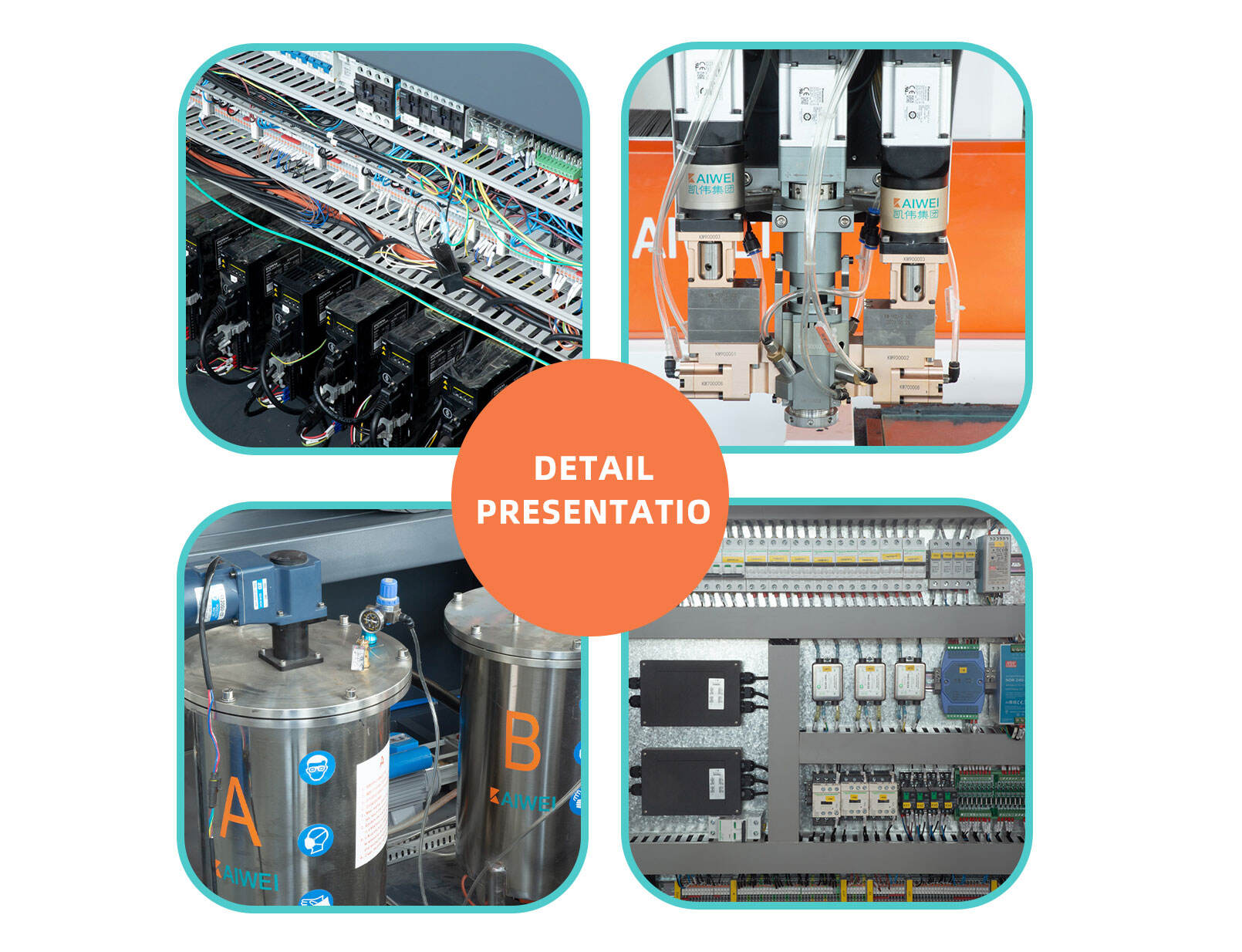

The KW-520 Automatic Foam Sealing Machine Form-In-Place Gasket Dispensing Pu Gasket Dispensing Machine is simply a item top-of-the-line because of the trusted name brand Kaiwei. This product is made to aid manufacturers have the working work done quickly and effectively by automating the entire means of foam sealing and dispensing.

This product features technology advanced enables you to utilize and very versatile. Its developed to use form-in-place (FIP) gasket dispensing and it is with the capacity of dispensing PU gaskets, making it a guitar valuable a range of applications.

Laden with an control advanced, the KW-520 Automatic Foam Sealing Machine Form-In-Place Gasket Dispensing Pu Gasket Dispensing Machine could possibly be programmed to dispense gaskets of varied shapes and sizes. This may allow it to be a thing manufacturers that are valuable need certainly to create big levels of gaskets with accuracy and persistence.

The KW-520 could be made with individual security in mind. It includes a system completely automatic eliminates the necessity for handbook intervention, reducing the chance of accidents as a result of operator mistake. In addition comes with an crisis end key which may be triggered when you would you like to prevent the dispensing straight away process just in case there clearly was any dilemmas.

Not only is it easy to use as well as efficient, the KW-520 normally extremely built and sturdy to endure. Produced from top-notch materials, this revolutionary product is built to withstand the deterioration of daily usage and it's also sustained by an assurance dependable producer.

You increase your productivity and effectiveness whether you are in the automotive, electronic devices, or other production companies, the KW-520 Automatic Foam Sealing Machine Form-In-Place Gasket Dispensing Pu Gasket Dispensing Machine is actually a valuable device that may help. Featuring its advanced features and performance dependable it really is an investment sure to stay into the run very long. Choose Kaiwei for the gasket requires being dispensing feel the things that are great good quality machinery.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

BN

BN

GU

GU

LA

LA

KK

KK

UZ

UZ