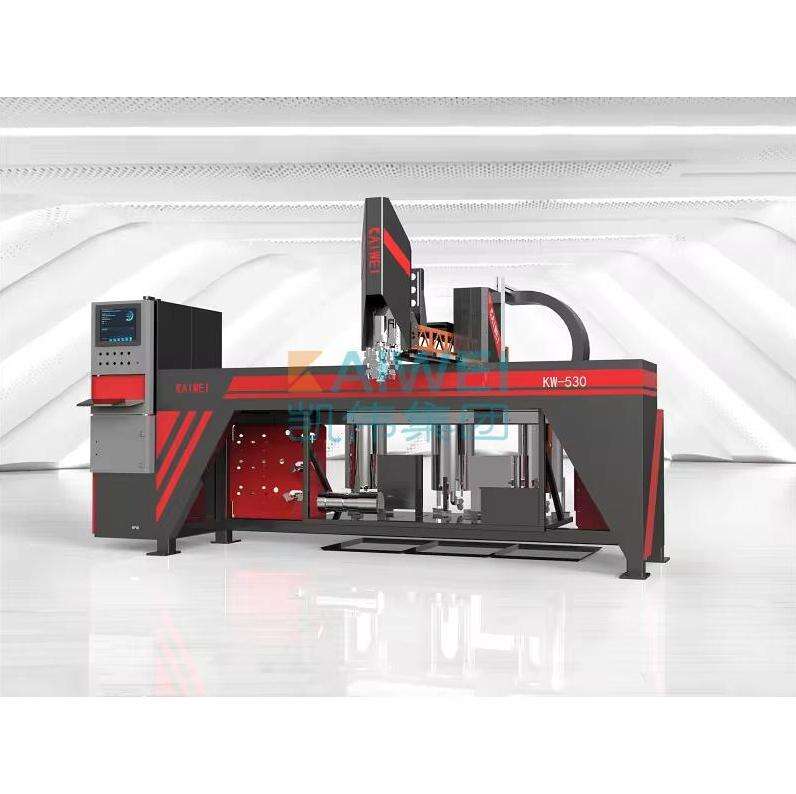

Electric Cabinet Polyurethane Gasket Dispensing Machine FIPFG Technology PU Gasket Machine 2024

- Overview

- Recommended Products

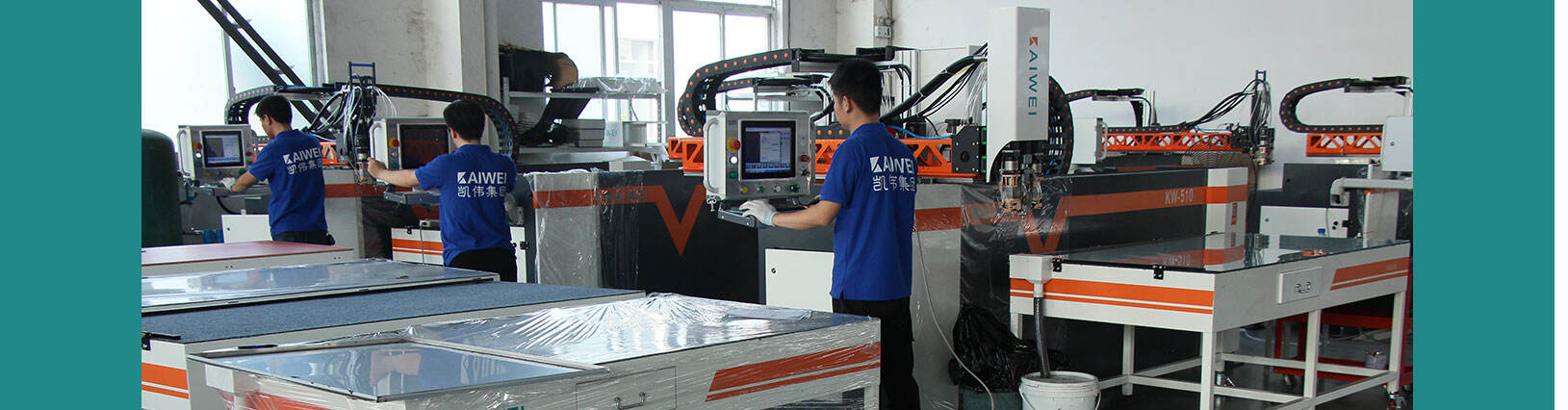

Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. was founded in 2004 and headquartered in Shanghai. As a high-tech enterprise, Kaiwei specialized in R & D and production of industrial sealing system and robot foaming equipment. The company has professional R & D institutions, perfect technical innovation system, and provides automation electrical solutions for well-known enterprises at home and abroad.

Q1: Are you a factory or trading Company?We are a professional machines manufacturer. Our headquarter is in Qingpu district, Shanghai, CN. Our factory located in Suzhou district, Jiangsu, CN. It only takes 30 mins from Hongqiao airport/train station to our headquarter, you are always welcome to visit us.

KAIWEI

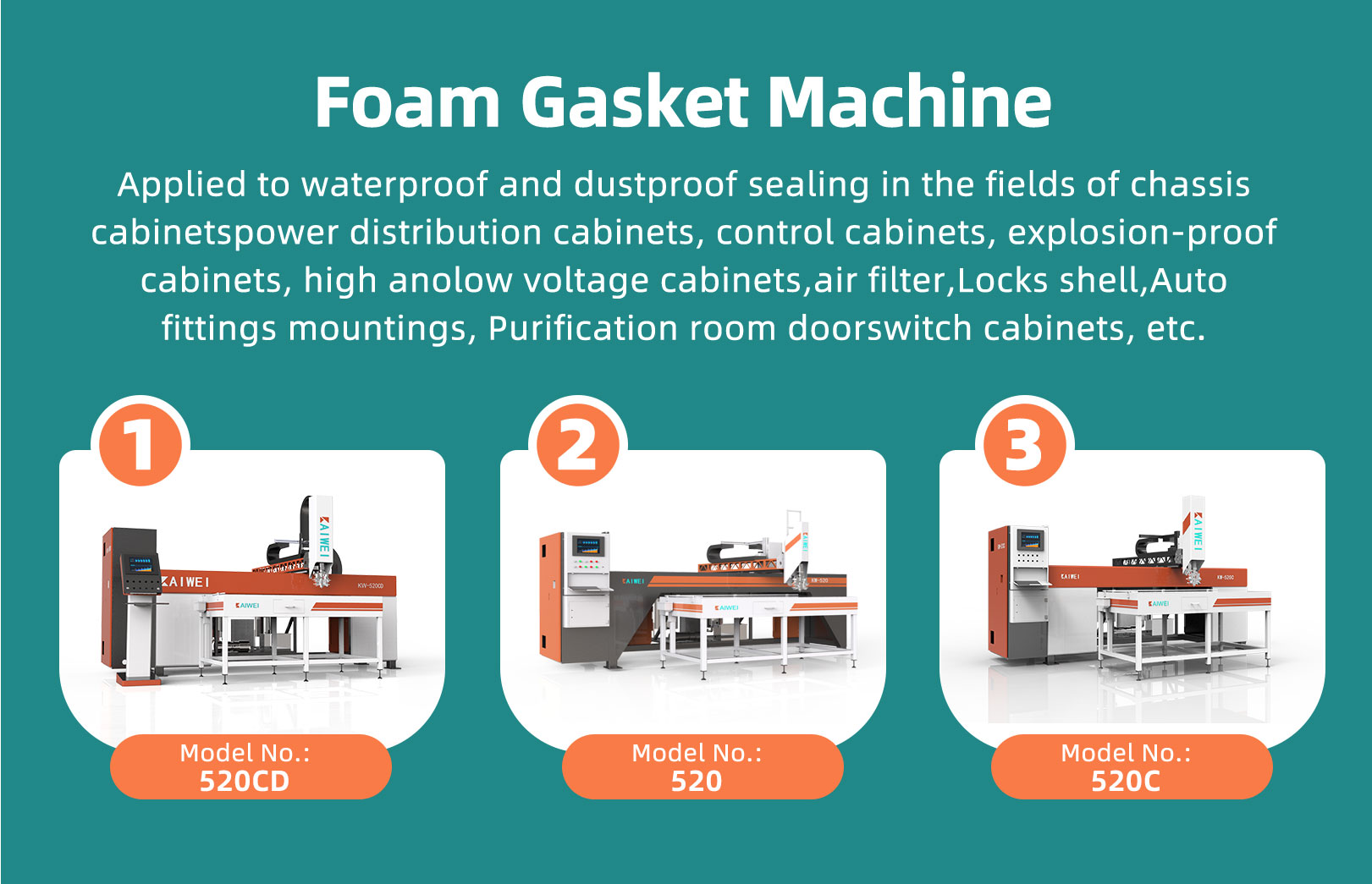

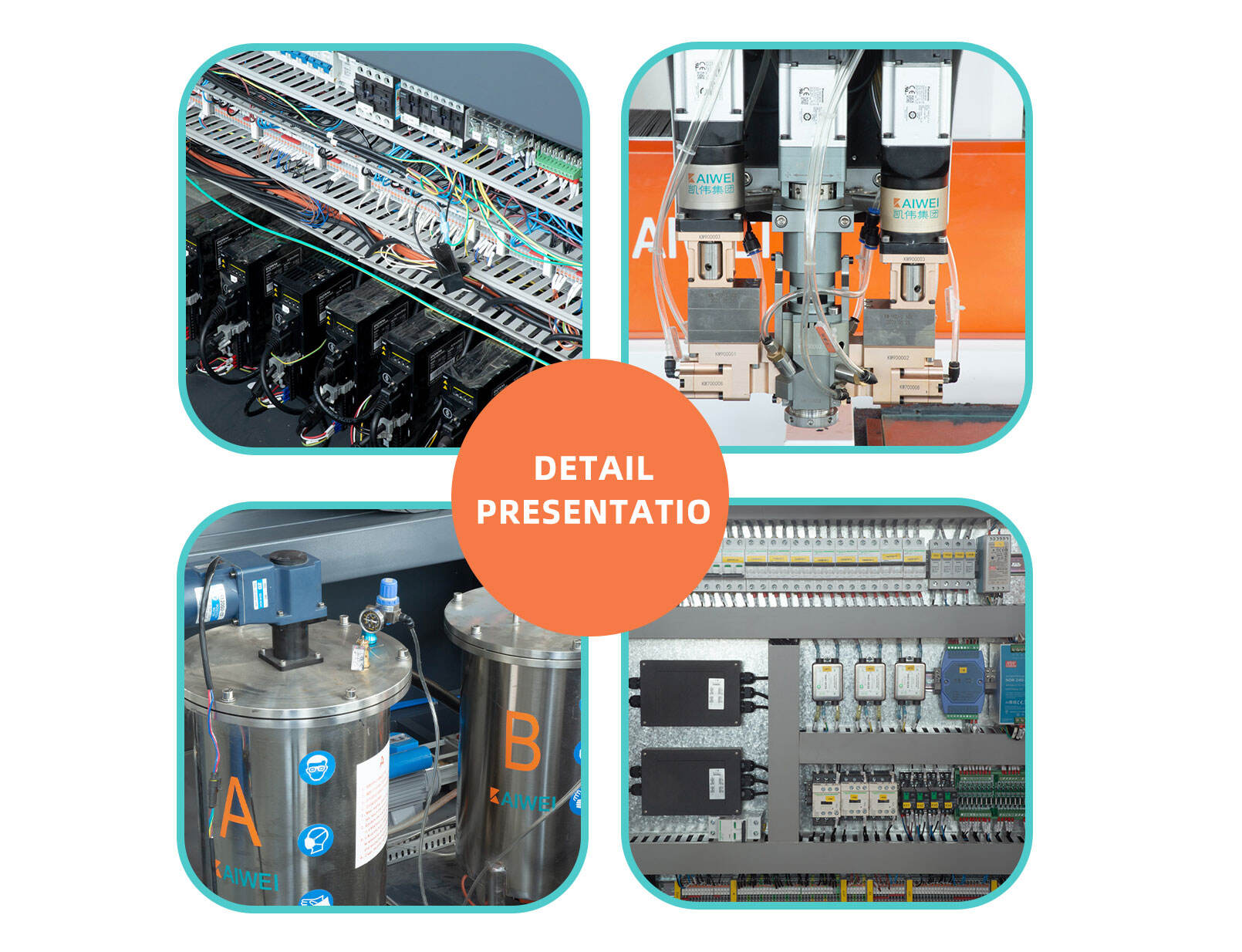

The Electric Cabinet Polyurethane Gasket Dispensing Machine is a state-of-the-art device that applies FIPFG technology to create precise and durable gaskets for electrical cabinets. This PU gasket machine 2024 is designed to dispense polyurethane foam on a variety of surfaces, allowing it to perfectly seal electrical cabinets and prevent dust, moisture, and other contaminants from getting inside.

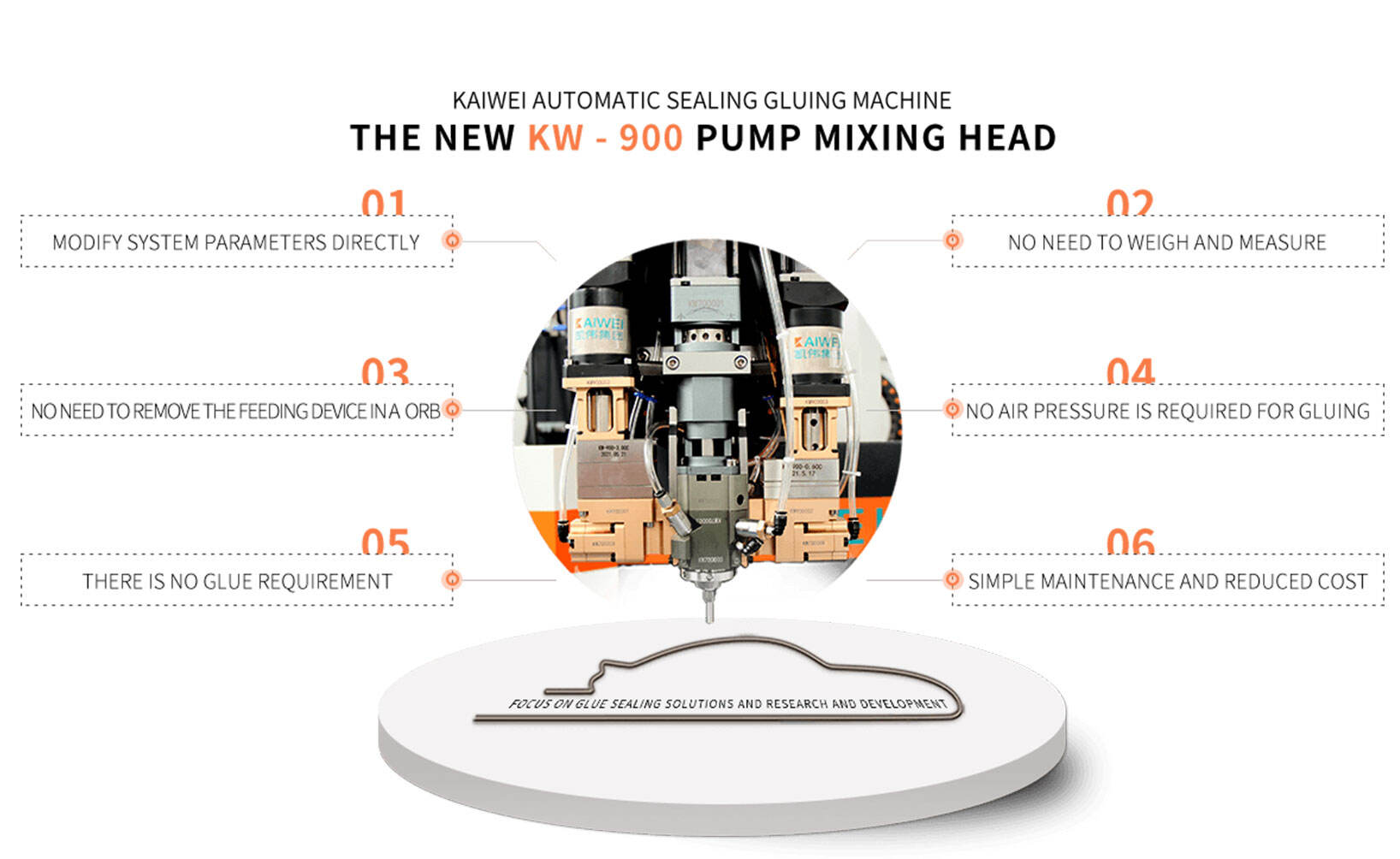

Straightforward to use and includes a user interface is user-friendly. It really is built with a servo is top-quality, ensuring smooth and accurate movement, plus an automatic eating system that ensures a steady flow of polyurethane. This ensures that your gaskets is constant each time and can have the depth is ideal each application.

Made with durability at heart. The cast-iron human anatomy and steel is stainless make certain that the device will withstand even the many demanding industrial surroundings, as the modular design allows for simple upkeep and repairs.

An investment is excellent any factory or maker seeking to create top-quality gaskets quickly and effortlessly. The equipment can produce up to 20 gaskets per minute, enabling manufacturing to be scaled up to meet with the demands of any project.

Not only is it simple to use and durable, this can also be highly versatile. It may be easily adjusted to support a number of applications, including gaskets for electrical cabinets, refrigeration units, and piping is commercial. This will make it an option is ideal a wide range of companies, including electronics, automotive, and production.

The Kaiwei Electric Cabinet Polyurethane Gasket Dispensing Machine is the perfect choice for any industrial application.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

BN

BN

GU

GU

LA

LA

KK

KK

UZ

UZ