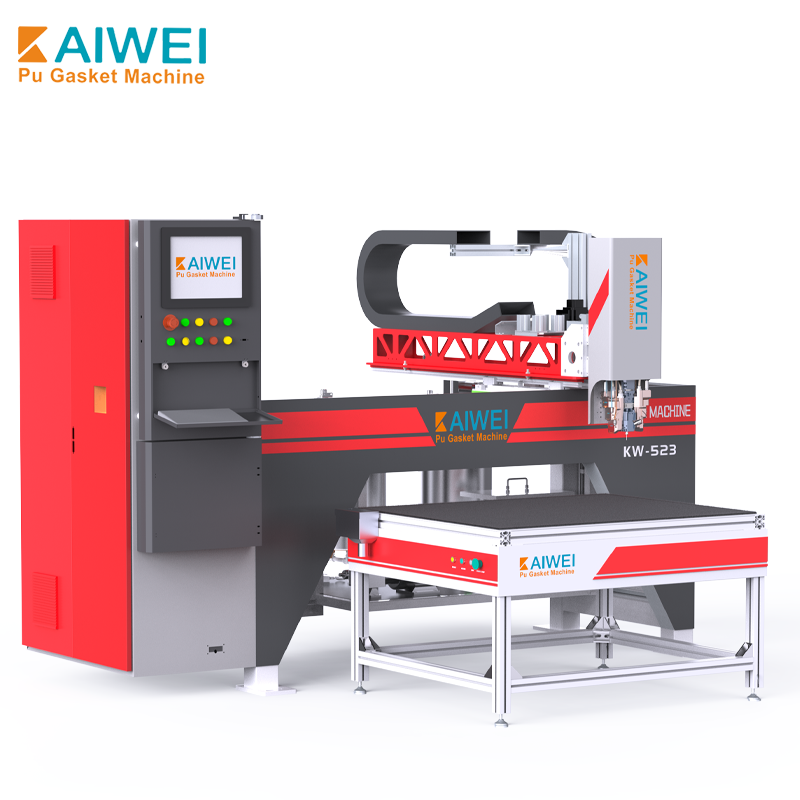

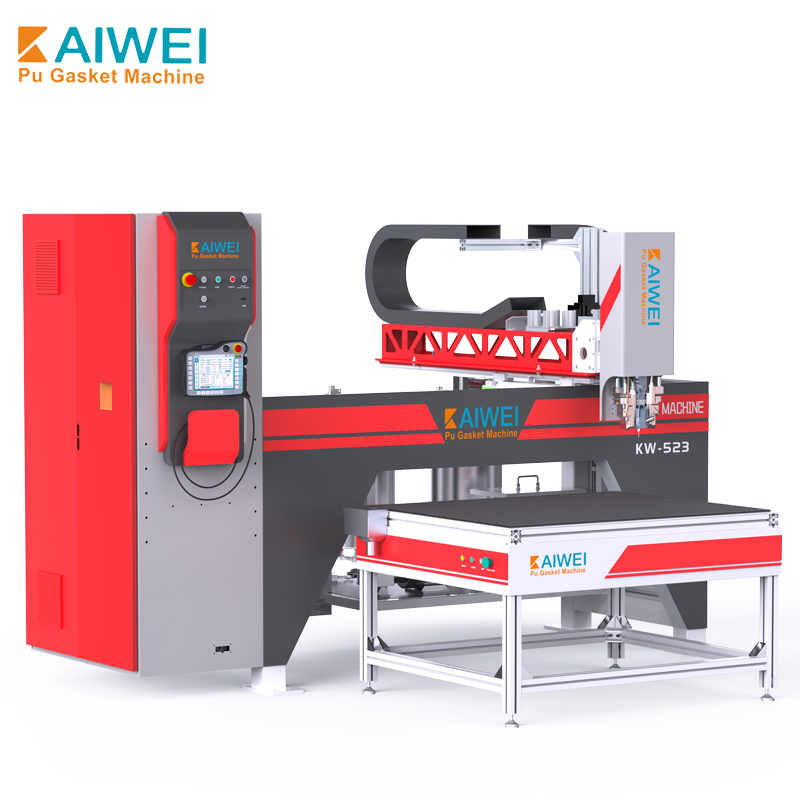

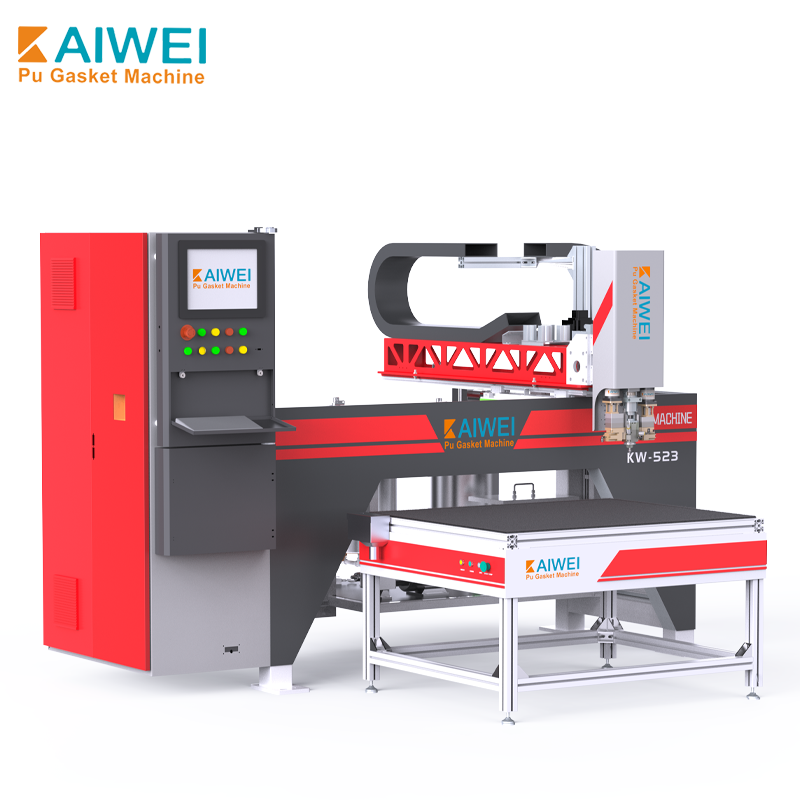

KW-523 Auto Seal Gluing Machine Electrical cabinet gasket machine Pu gasket tire fill machine manufacturers China

- Overview

- Recommended Products

Shanghai Kaiwei intelligent Technology (Group) Co., Ltd., established in 2004, is a high-tech enterprise with over 22 years of expertise in industrial automation and innovation.

We specialize in the R&D and production of pu gasket dispensing machine and robot foaming equipment, providing applications including electrical cabinet, air filter, air conditioning purification lamps,automotive new energy and other fields.

Our products hold internationally recognized certifications such as SGS,CCC, CE, ingress Protection, and lS09001,MSDS,RoHS,ensuring high quality and compliance with global standards for safety and performance.

FAQ

Q: KAlWEl automatic foam sealing machines

F: KAlWEl automatic foam sealing machines are based on ROOTCLOUD industrial internet platform which can realize 24-hour global networking distant monitoring and solve the failures online.

Q: KAIWEl was a user of automatic foam sealing machine before

F: KAWEl was a user of automatic foam sealing machine before, then independently developed the machine, and made it more reliable and simpler. KAlWEl machine solves high maintenance cost, complex operation and other technical problems.

Q:The sealing gaskets made by KAlWEl machines have passed the international

F:The sealing gaskets made by KAlWEl machines have passed the international authoritative organization test: lP56,lP66,IP67

Q:KAlWEl has more than 20 patents for machine hardware and software

F:KAlWEl has more than 20 patents for machine hardware and software, updating operating system software for free.

Q:KAlWEl machines adopt the integrated design

F: KAlWEl machines adopt the integrated design, smaller space and easier installation.

The KW-521 Auto Seal Gluing Machine Electrical cabinet gasket machine Polyurethane spray foam insulation machine is truly a device essential whoever desires a dependable and effective method towards utilize gaskets, glues, in addition to various other securing items and solutions. It is a situation electrical gadget created to become extremely easy to use, along with user friendly setups and a treatment simple. This progressed gadget has a building durable was produced towards last.

Its own body is built of first-class products which might endure deterioration, ensuring it will remain fixed in remarkable problem for several years. Making it the choice perfect requests that are industrial where resilience and reliability are important.

The KW-521 creates use of greater degree innovation towards try a wide range of gasket and sticky kinds, consisting of polyurethane spray foam insulation. This might create it a device flexible could be used in a number of different requests, coming from securing cupboards and enclosures towards insulating frameworks together with various other frameworks. Its own polyurethane spray foam insulation work is fantastic for those attempting to enhance energy efficiency, decrease noise, and create a much comfier lifestyle or even location functioning. The KW-521 assists you towards reduce energy squander and decreased expenses in industrial and setups that are residential splashing foam insulation into wall surfaces, roofs, and floorings.

The KW-521 Auto Seal Gluing Machine Electrical cabinet gasket machine Polyurethane spray foam insulation machine is an aspect connected with Kaiwei items, comprehended for the high quality and satisfaction exceptional. Possessing a performance history of producing reliable and devices resilient Kaiwei is truly a headline relied on the marketplace. Customers are specific that their KW-521 will provide results which are excellent opportunity they typically use it. The system is developed to become light-weight and small, making it simple towards transfer and exercise use on-site.

Its own dimension little bit of and simple guarantee it is perfect for utilized in limited locations and hard-to-reach locations. Another beneficial possession of the KW-521 Auto Seal Gluing Machine Electrical cabinet gasket machine Polyurethane spray foam insulation machine is that you have the ability to quickly maintain, along with simple cleaning treatments and a requirement very little maintenance. It will assist towards conserve cash and opportunity within the operate incredibly making lengthy a cost-effective service for company individuals and homeowner as well.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

BN

BN

GU

GU

LA

LA

KK

KK

UZ

UZ