KW-520 polyurethane injection machine dry foam soft cleaning machine FIPFG technology for electrical cabinet

- Overview

- Recommended Products

Shanghai Kaiwei Intelligent Technology (Group) Co., Ltd. was founded in 2004 and headquartered in Shanghai. As a high-tech enterprise, Kaiwei specialized in R & D and production of industrial sealing system and robot foaming equipment. The company has professional R & D institutions, perfect technical innovation system, and provides automation electrical solutions for well-known enterprises at home and abroad.

Q1: Are you a factory or trading Company?We are a professional machines manufacturer. Our headquarter is in Qingpu district, Shanghai, CN. Our factory located in Suzhou district, Jiangsu, CN. It only takes 30 mins from Hongqiao airport/train station to our headquarter, you are always welcome to visit us.

Our engineers are also available to serve on abroad.

KAIWEI

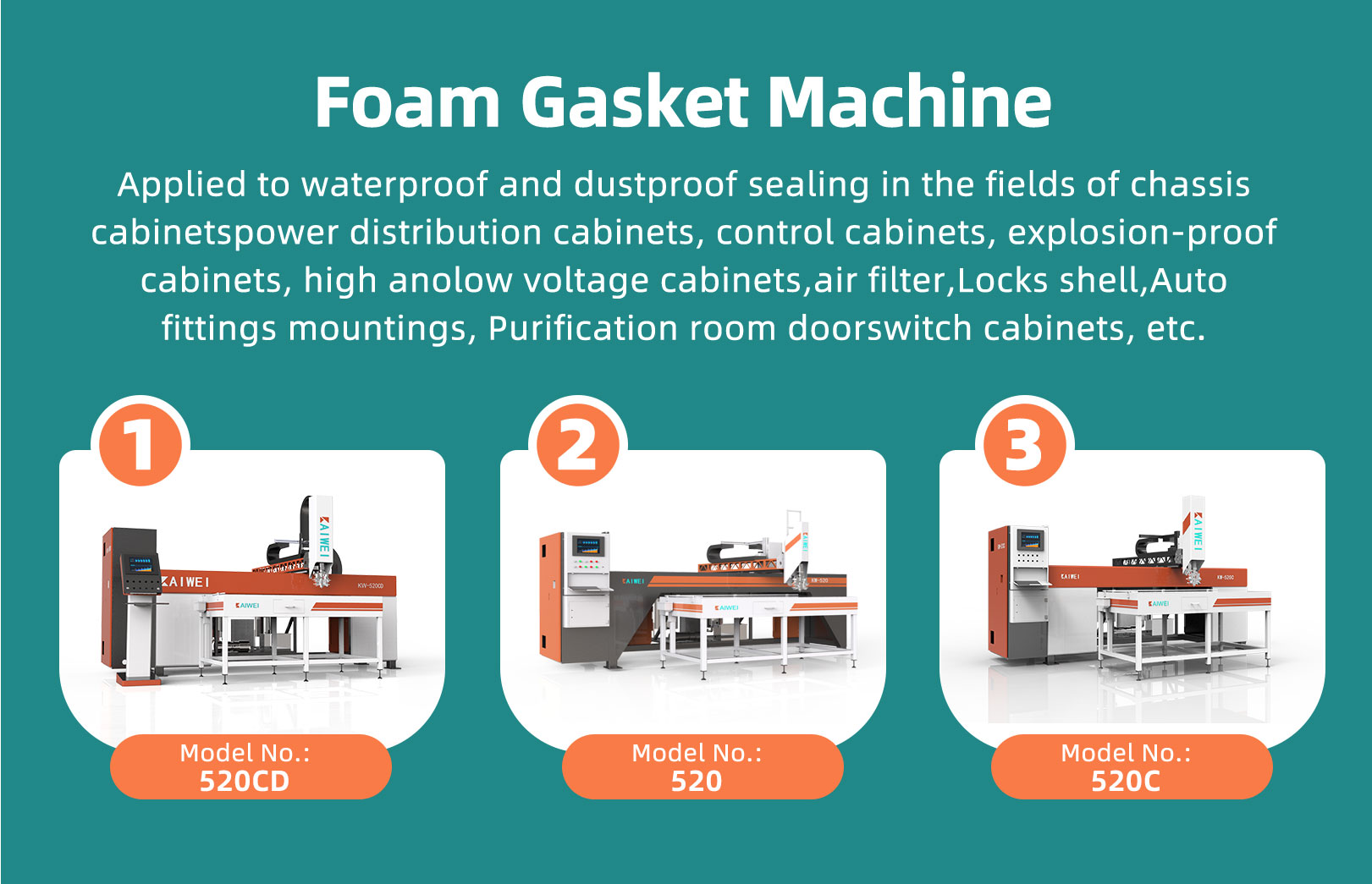

Presenting the KW-520 polyurethane shot device completely dry out foam smooth cleansing device, an innovative item coming from Kaiwei.

Are you sick of having a hard time towards cleanse your electric cupboard? Are actually you continuously stressed over harming your delicate electric elements throughout the cleansing procedure? Look no more compared to the KW-520.

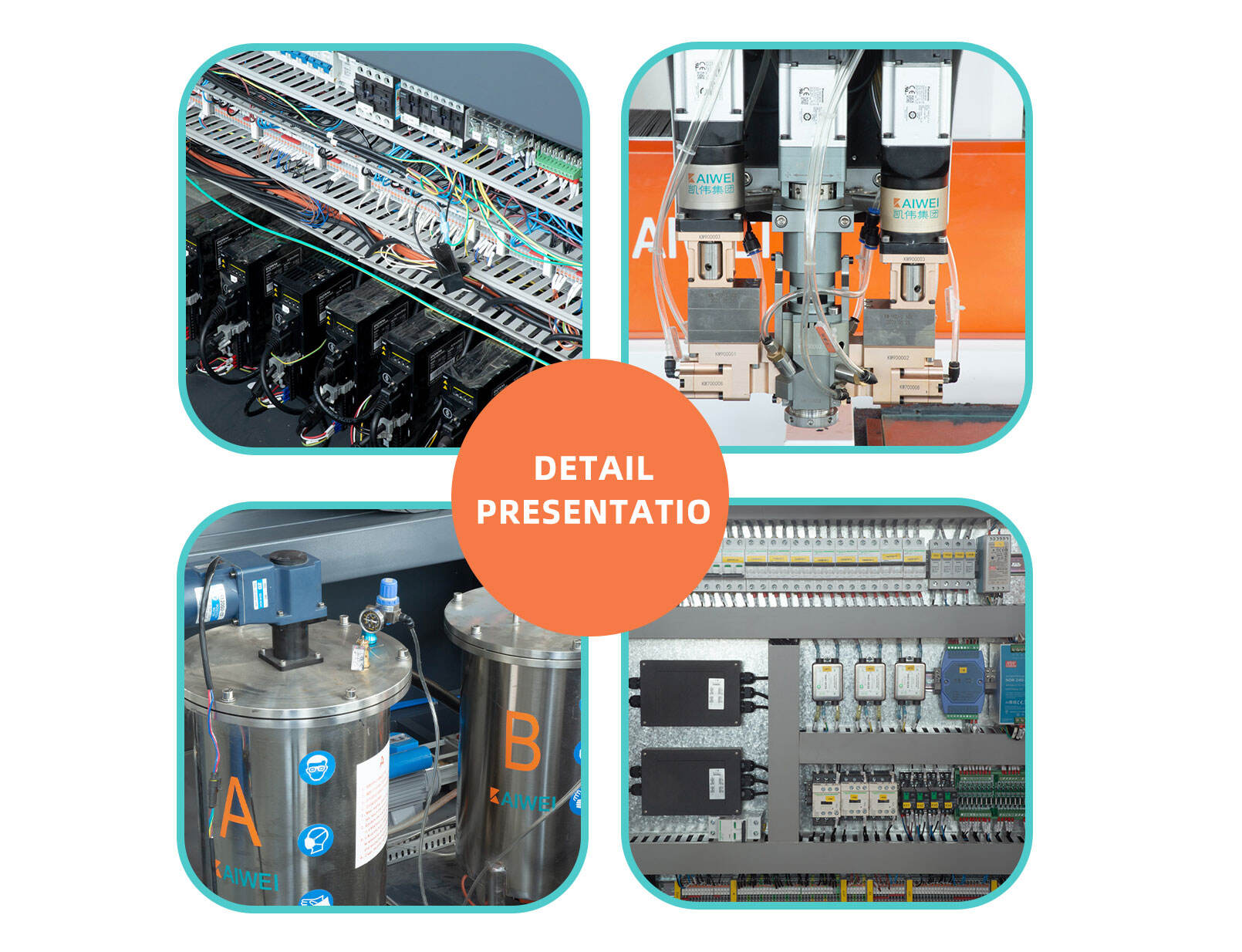

Developed along with FIPFG innovation, this polyurethane shot device foam is completely dry out cleansing device offers an effective risk-free cleansing service for your electric cupboard. Its own top quality elements smart style ensure that the fragile electric elements remain safeguarded while providing you a efficient, comprehensive, cleanse is mild.

Along with user friendly manages, likewise those without technological proficiency can easily run this device easily. Just tons the foam is suitable press the switch, along with KW-520 performs the remainder. The foam is completely dry out cleaning service is particularly developed towards puncture oil gunk while being risk-free for your electrical equipment. Since it is polyurethane-based, it is eco-friendly, that makes it the option is ideal anybody wanting to decrease their carbon dioxide impact.

Flexible sufficient towards utilize in a variety of setups, like information centers, telecommunication centers, digital manufacturing, commercial command a lot more, cupboards. Its own small dimension style is light-weight it the ideal service for each off-site and on-site cleansing requirements.

Furthermore guaranteed that the KW-520 is designed towards final. The machine's durable building implies it might endure use is hefty it includes a 1 year guarantee towards deal you included tranquility of mind. Upkeep can easily be a wind lots of because of its own style is modular implies that any type of components or even elements could be just altered if required.

The KW-520 polyurethane shot device completely dry out foam smooth cleansing device is a game-changer for anybody searching for a much safer, much a lot extra effective, much a lot extra efficient method towards cleanse their electric cupboard. Along with its own ingenious style, easy to use manages, effective cleansing abilities, it is the ideal service for anybody wanting to enhance their cleansing procedure while safeguarding their important electric devices. Therefore why hang around? Attempt the KW-520 today view the distinction it can easily create.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

BN

BN

GU

GU

LA

LA

KK

KK

UZ

UZ